doi: 10.56294/dm2023200

ORIGINAL

A model for Industry 4.0 readiness in manufacturing industries

Un modelo de preparación para la Industria 4.0 en las industrias manufactureras

Younes Jamouli1,2 ![]() *, Samir Tetouani1

*, Samir Tetouani1 ![]() *, Omar Cherkaoui1

*, Omar Cherkaoui1 ![]() *, Aziz Soulhi2

*, Aziz Soulhi2 ![]() *

*

1LINA Laboratory, Higher School of Textile and Clothing Industries. Casablanca, Morocco.

2Systems management and engineering Team, National Higher School of Mines. Rabat, Morocco.

Citar como: Jamouli Y, Tetouani S, Cherkaoui O, Soulhi A. A model for Industry 4.0 readiness in manufacturing industries. Data and Metadata. 2023;2:200. https://doi.org/10.56294/dm2023200

Submitted: 16-09-2023 Revised: 08-11-2023 Accepted: 28-12-2023 Published: 29-12-2023

Editor: Prof.

Dr. Javier González Argote ![]()

ABSTRACT

In the context of digital transformation, to assess the current state of manufacturing companies, a readiness model is proposed in this paper. Using a literature review and a framework considering maturity as an ‘input’ enabler and not as an ‘output’. Three dimensions are considered in this model (Organization maturity, Technology maturity, and Process Maturity), to assess the company readiness (Ready or Not ready). Allowing compagnies to identify their readiness for Industry 4.0 (I4.0) adoption, by developing a decision support model, is the goal of this research. This model based on Fuzzy Inference System, considers the three decision criteria and then ranks the enterprise according to its output indicator. For the validation of this proposed model, an experimental study was conducted to assess the readiness of 2 manufacturing companies, a multinational in automotive sector and an SME in Apparel sector. The proposed model meets the desired objective and is therefore retained for the evaluation of the readiness to I4.0 in different manufacturing contexts.

Keywords: Digital Technologies; Readiness Model; Adoption; Fuzzy Logic.

RESUMEN

En el contexto de la transformación digital, para evaluar el estado actual de las empresas manufactureras, se propone en este artículo un modelo de preparación. Utilizando una revisión de la literatura y un marco que considera la madurez como un habilitador ‘de entrada’ y no como un ‘resultado’. En este modelo se consideran tres dimensiones (Madurez de la organización, Madurez tecnológica y Madurez del proceso) para evaluar la preparación de la empresa (Preparada o No preparada). El objetivo de esta investigación es permitir a las empresas identificar su preparación para la adopción de la Industria 4.0 (I4.0) mediante el desarrollo de un modelo de apoyo a la toma de decisiones. Este modelo, basado en un Sistema de Inferencia Difusa, considera los tres criterios de decisión y luego clasifica la empresa según su indicador de salida. Para la validación de este modelo propuesto, se llevó a cabo un estudio experimental para evaluar la preparación de dos empresas manufactureras, una multinacional del sector automotriz y una PYME del sector de la confección. El modelo propuesto cumple con el objetivo deseado y, por lo tanto, se retiene para la evaluación de la preparación para I4.0 en diferentes contextos de fabricación.

Palabras clave: Tecnologías Digitales ; Modelo de Preparación ; Adopción ; Fuzzy Lógica.

INTRODUCTION

Cyber-physical systems and digital transformation technologies are fostering the relevant process of merging the digital, physical and biological worlds; This is the current Industry 4.0 (I4.0) (ISCOOP, 2022). Big Data, Cloud Computing, Artificial Intelligence (AI), Industrial Internet of Things, and Cybersecurity, are some of technological enablers for new production systems through I4.0.(1) In other words, Production processes and business models are transformed due to market pressure and new technology paradigms, therefore, the organization and control of the industrial value chain are facing a new era.(2) In the context of I4.0, the technological dimension is often dominant within the maturity models or the readiness models, it is at the center of discussion.(3) These data can be used to develop better implementation methodologies, understand current pitfalls, and compare companies and their performance. In the firm level, quantifying the current maturity of the organization to assess the readiness for implementing I4.0, is recommended regardless of organizational and industry enablers.(4)

Activities of companies towards Industry 4.0 should be divided into organizational and technological from a project management perspective.(5) According to the process-based approach, companies have three types of processes: business processes, organizational processes, and managerial processes. The focus is on the value under the concept of the product life cycle, to analyze maturity,(6) starting from product development, process development, procurement, and manufacturing.(7) Furthermore, many authors highlighted the fact that to succeed in a smart manufacturing environment, companies must have a certain degree of readiness.(8,9) Readiness Models help systematically gather information about a company’s current state and its strategies for I4.0, so they are useful for both science and practice.

Felippes et al.(7) propose the ‘3D-CUBE Readiness Model,’ which relates technological, organizational and process maturity enablers as dimensions for evaluating a company’s readiness to implement Industry 4.0. Technological dimension includes two sub-dimensions: Production technology and Information technology; Organization dimension includes two sub-dimensions: people (which in turn has four elements: Leadership, Communication, Training, Culture of Innovation) and strategy; Process dimension includes two main sub-dimensions: Product-service development and Order fulfillment. Indeed, many authors are considering the need to analyze ‘process maturity’ in a readiness model. Felippes et al.(7) compared existing maturity and readiness models, identified the current problems and limitations in these approaches, and describe the new 3D-CUBE Model. Hizam-Hanafiah et al.(10) conducted a systematic literature review and identified 30 existing Industry 4.0 readiness models from both industry and academia. These models are based on 158 dimensions used by different authors and firms to evaluate Industry 4.0 readiness. In fact, the original contribution of this review is that it provides the six most common dimensions pooling from 158 individual dimensions, deriving from 30 existing Industry 4.0 readiness models. These dimensions can be considered as the most important dimensions for most of the organizations, irrespective of their size and industry, they are six (Technology, People, Strategy, Leadership, Process and Innovation). To improve and reinforce their readiness for Industry 4.0, companies should be based on the main dimensions of the readiness regarding Industry 4.0. These dimensions are:

Technology, organization, and process

In this paper, Fuzzy logic is presented as a connected and controlled tool that allows companies to implement the necessary corrections. First, the approach is described, and the major criteria related to the Enterprise’s readiness for Industry 4.0 adoption are defined. Next, the modeling of these factors(11) is presented through the use of membership functions. Following that, the development of decision rules is undertaken, and finally, the results are analyzed.

Literature review

The AHP (Analytic Hierarchy Process) method developed in 1980 by Saaty (1980) allows solving complex problems with multicriteria. In the industrial field, criterion has its value, the problem arises in the classification of criteria according to the order of priority for each company.(12) That is, it is difficult to classify them according to the order. Multi-criteria decision-making methodologies including: The network process (AHP), scoring models, over ranking, goal programming, expert systems, data envelopment analysis, etc.” Tachibana et al.(13), share some common characteristics such as the conflict between criteria and incomparable units.(14) Therefore, other technics of decision making like PROMETHEE and ELECTRE are widely applied in different fields such as academic literature.(15) An extension of linear programming, goal-based programming which allows solving multiple-goal problems, but the problem arises to provide appropriate weights.(16,17) Decision-making tools are very useful tools in different domains with different factors, especially to determine an appropriate solution it is a difficult task.(17) Rezaei(18) used BWM to solve multi-criteria decision-making (MCDM) problems. Author stated “Statistical results show that BWM performs significantly better than AHP’s inconsistency ratio and other evaluation criteria: minimum violation, total deviation, and compliance (...). According to BWM, the best (e.g., most important) and worst (e.g., least important) criteria are defined by the decision-maker. Pairwise comparisons are then made between each of these two criteria (best and worst) and the other criteria”.

Contrary to binary logic, Fuzzy logic allows for better modeling of intuitive parameters via membership functions, interconnected through fuzzy rules, which is a mathematical object. It is presented as a connected and controlled tool that allows companies to implement the necessary corrections. Fuzzy logic was first formulated by mathematician Lotfi Zadeh in the 1960s. The advantage of the adopted method over other MCDM decision making methods adopted in the literature is its ability to model intuitive indicators via membership functions. In fact, other MCDM methods require a complete recalculation of the data. Moreover, the model developed provides the ability to verify the I4.0 readiness of a company.

METHODS

Fuzzy Logic

Fuzzy logic formalized by Lotfi Zadeh, is based on the mathematical theory of fuzzy sets, which is an extension of the classic set or the degree of truth of a function takes one of two values (true or false) or (0 or 1) in binary.(19) It is used in artificial intelligence, in fields of robotics, mechanics, traffic management (red lights) and many other areas. Authors in Haleh et al.(20) stated “The fuzzy logic confers thus a very appreciable flexibility to the reasonings which use it, which makes it possible to take into account the imprecisions and the uncertainties”. The rules are drawn up in natural language, it is one of the interests of fuzzy logic to formalize human reasoning.(21) To understand the use of fuzzy logic to evaluate the readiness of a company to implement I4.0, the following sections present the principles of this logic and its inference process.

The fuzzy set and linguistic variable concepts

Fuzzy logic accepts degrees of membership to a set, instead of being associated with a set of true or false values. A membership function is linked to a variable’s value, and the membership factor is calculated by a number between 0 and 1. This concept allows to assign a membership function which goes from 0 to 1 in order to allow gradations in the membership of an element to a class, i.e. to allow an element to belong more or less strongly to this class;(22) the fuzzy subsets are thus useful to represent the imprecision of the inputs or the uncertainty related to the implemented knowledge.

Figure1. Range of logical values in Binary (a) and Fuzzy logic (b)

Figure 2. Classic and fuzzy sets(23)

The figures 1 and 2 illustrates the difference between the functions of membership of the classic logic and the fuzzy logic. In the 1st, the appearance is binary 0 or 1, in mathematical term, a variable “ X “ is it contains to a set “ E “ or not, on the other hand in the 2nd the degree of appearance is a numerical value which varies in the interval [0 ;1]. Moreover, this variable can belong to several sets at the same time contrary to the classical logic. Figure 2 is a synoptic outline of a fuzzy system that will be approached thereafter.

Figure 3. Fuzzy rule-based system schematic(34)

Step 1: definition of linguistic variables: a fuzzy inference system is a system composed of three big bricks: the fuzzification, the inference engine and the defuzzification (Figure 3). The inputs of the fuzzy inference system are the scores assigned to each variable in the decision-making process, which need to be quantifiable.(23)

The first part that will allow to translate a numerical data coming from a sensor into a linguistic variable is called fuzzification. Thanks to a membership function created by the fuzzy system designer. A membership function is a function that allows to define the degree of membership of a numerical data to a linguistic variable.(24) Membership functions can theoretically take any form as in figure 4. However, they are often defined by functions: triangular, rectangular, Gaussian.

Figure 4. Types of membership functions(29)

This first step of fuzzification will translate the numerical data of the sensors into different linguistic variables. Fuzzy logic thus makes it possible to integrate expert systems into automated processes.(25) “This point is both a strength and a weakness of fuzzy logic”.(26)

Step 2: fuzzy inference: now that we have linguistic variables, we can pass them into the inference engine. Here, “each rule of the inference engine is written by the designer of the fuzzy system according to the knowledge he has”.(27) The initial step for this second part is to enumerate all known rules that apply to the system. A rule must be in the form If condition, then conclusion. Then, fuzzy inference is the construction of rules (and results) based on linguistic variables, assigning a truth to each rule, then aggregating the rules to obtain a single (linguistic) result. The challenge with inference rules is to know what the logical operators mean. Indeed, the operators of classical logic (AND, OR) are no longer valid in fuzzy logic.(28) Therefore, it is necessary to redefine them, as illustrated in figure 5:

Figure 5. Operations on fuzzy sets(35)

The inference engine is the stage where the “If..., then...” decision rules will be parameterized.

Through the utilization of this engine, the application of the established rules to the fuzzy input variables becomes feasible.(29)

Step 3: defuzzification “Inference methods provide a resulting membership function µX of the output variable x”. It is therefore fuzzy information. It is necessary to transform this fuzzy information into a given value that will be applied to the process control interface. This transformation is called defuzzification. The most used defuzzification method is the determination of the center of gravity.(22)

Fuzzy inference system description

The fuzzy inference system shown in this figure (Figure 6) consists of three parts:

Figure 6. Steps of fuzzy logic(30)

Case study

Indicators Definition

A company can be qualified as ready to implement Industry 4.0 if it meets the requirements in terms of maturity of its organization, its technology and its processes. A brief description of these criteria follows:

Organization maturity: organizational maturity depends on two elements, Organizational strategy and workforce. Organizational strategy deals with the necessary support and philosophy that a company must have to enable organizational change. Workforce or Human Factors (HF) are probably the major enabler of I4.0. With the rise of I4.0, employees will need to be empowered across all organizations and along the value chain to be agile and strategic in dealing with new challenges. The human workforce includes ‘leadership’, ‘communication’, ‘training’, and a ‘culture of innovation’.(7)

Technology maturity: technological dimension includes two sub-dimensions: Production technology and Information technology. Production technology aims at supporting humans in their increasingly complex work context and is one of the most prominent research areas in I4.0.(7) Information technology is differentiated into the following elements: ‘data collection, analysis, interconnectivity, and transparency’, ‘information security’, and ‘decentralized decisions’.

Processes maturity: to analyze this maturity, The focus is placed on the value within the concept of the product life cycle, including product-service development and Order fulfillment. Product-service-based development addresses the effort to meet customer requirements based on customization, product-service systems, and shared manufacturing, and implies a simultaneous development of products and services. The order fulfillment sub-dimension integrates the entire manufacturing process, from production to product delivery.(7)

As an output function, there is the I4.0 Readiness Score, which is a number between 0 and 1, reflecting the degree of readiness of the company to adopt I4.0 technologies. The closer its value is to 1, the more ready the company is, and the closer it is to 0, the more unready the company is. Thus, the model will be schematized as follows (Figure 7):

Figure 7. Parameters Presentation

Modeling of Indicators

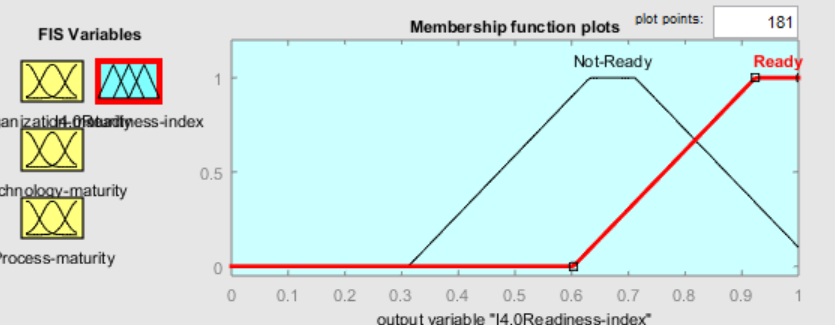

Indicator modeling is characterized by transforming variables into fuzzy variables (also called linguistic variables) by associating veracity laws to them. The figure below (Figure 11) shows the I4.0 Readiness membership function µ (Readiness) to a universe of discourse with subsets < Ready, not ready> using Mamdani as the inference type. The I4.0 Readiness variable is divided into modalities (Ready and Unready).

The other indicators are modeled (Figure 8,9 y 10) by the same principle by membership functions of different type using linguistic terms appropriate to each indicator.

Figure 8. Organization-maturity membership function

Figure 9. Technology-maturity membership function

Figure 10. Process-maturity membership function

Figure 11. The output I4.0 Readiness-Index Membership function

Fuzzy Inference

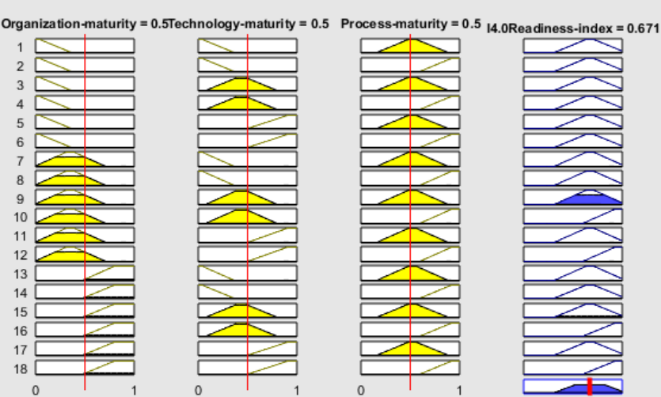

The part where the experts define the fuzzy rules (Figure 12) using the set of input indicators.(31) In this case study, 18 fuzzy rules were established (3*2*3) with the <and> operator.

Defuzzification

Graphically, the following figure shows the defuzzification step, which consists in transforming the fuzzy set associated with the inputs: organization maturity, Technology maturity and Process maturity into a net value by applying the center of gravity method.

Figure 12. Visualization of decision rules

RESULTS AND DISCUSSION

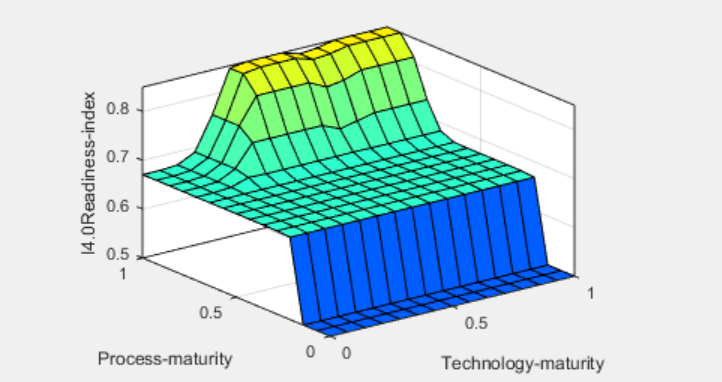

The surface represents the three-dimensional relationship between the various inputs and outputs. Relationships depend on the rules made.(32) The very random fluctuations on the surface represent weaknesses and at the same time indicate the wrong development of the established rules. To analyze the surfaces, working with only 2 inputs, the third one is set to a constant value (abscissa axis), and the result of the output is visualized on the coordinate axis.

Case N°1: (Med, Y, Z)

In this case the Organization maturity indicator is set as Medium (Figure 13)

Medium: organization maturity.

Y: technology maturity.

Z: process maturity.

Figure 13. The Cube for Case N°1: (Med, Y, Z)

When considering the Organization criterion as an average value, an analysis of the graph reveals that the I4.0 Readiness score is high when technology maturity is high, indicating the significance of this criterion. Conversely, the score is low when process maturity is low. Likewise, a medium score can be assigned to an enterprise with high technological maturity and low process maturity.

Case N°2: (X, Med, Z).

In this case the indicator of the Technology maturity is fixed in moderate (Figure 14).

X: organization maturity indicator.

Med: technology maturity Indicator.

Z: process maturity indicator.

Figure 14. The Cube for Case N°2: (X, Med, Z)

The displayed surface shows that the I4.0 Readiness score is small when the process is not mastered. However, the score is High when the input indicators (Organization, Process) are respectively (High, Mastered) or (Medium, Mastered). Similarly, a medium score can be assigned to an enterprise with a process that is moderately mastered to fully mastered. The results obtained are not found in binary logic where the I4.0 readiness score will be null if only one of the input parameters is null, hence the advantage of fuzzy logic. This simulation is a direct projection to the decision rules set up by the experts, hence the usefulness of modifying these rules, if necessary, by restoring the rules and allocating the appropriate membership functions to each input variable. The model allows to rank enterprise readiness for I4.0 according to its scores. Moreover, the surface gives a vision on the weighting of the input parameters to determine the predominant ones. The result obtained is associated to each company, since it is the experts in consultation with the company that defines in advance the weighting of the input criteria and the one among them that matters the most. If the results obtained are inconsistent with the requirements of I4.0, then the experts are invited to adjust the fuzzy rules or to redefine the membership functions of the variables.

CONCLUSION

The current Industry 4.0 (I4.0) can be understood as a relevant process of merging the physical, digital, and biological worlds through digital transformation technologies and cyber-physical systems (ISCOOP, 2022). I4.0 has technological enablers for new production systems, like Big Data, Cloud Computing, Artificial Intelligence (AI), Industrial Internet of Things, and Cybersecurity. It represents a new stage in the organization and control of the industrial value chain since new technology paradigms and market pressure have transformed production processes and business models.(33) This research proposes a Readiness Model, which relates technological maturity, organizational maturity, and process maturity enablers as dimensions for evaluating a company’s readiness to implement Industry 4.0.

This paper demonstrates the feasibility of constructing an artificial intelligence model based on fuzzy logic theory, enabling companies to evaluate their readiness for adopting I4.0. As a result, the enterprise has more chance to succeed in this transition. The integration of AI via fuzzy logic is an innovative NDT solution that enables fast and highly efficient dimensional or surface condition inspections. It is a solution that takes only minutes, and its footprint remains. Although it is a decision support tool for evaluating I4.0 readiness in different manufacturing industries, the proposed models based on fuzzy logic theory require a thorough study of I4.0 Readiness parameters by domain experts before companies can establish relationships between them. The results obtained vary considerably with changes in these fuzzy relationships that reflect the weights of different decision parameters, so the model is very challenging. The ingenuity of the model lies in its ability to model and adapt the decision criteria to the specific requirements of each manufacturing sector by assigning weights, directly influencing the decision rules. Subsequently, a unique model tailored to the domain can be developed based on the influential criteria. The main objective of this study is to exploit the knowledge of experts to establish decision rules and artificial intelligence to use them and establish a model based on fuzzy logic to ensure succeed the digital transformation of manufacturing companies.

REFERENCES

1. Jazdi, N.(2014). Cyber-phisical systems in the context of Industry 4.0. IEEE/AQTR,1–4, Romania: IEEE (Institute of Electrical and Electronics Engineers). https://doi.org/10.1109/AQTR.2014.6857843

2. Zhong, R., Xu, X., Klotz, E., & Newman, S. T. (2017). Intelligent manufacturing in the context of industry 4.0: A review. Engineering, 3(5), 616–630. https://doi.org/10.1016/J.ENG.2017.05.015

3. Schneider, P. (2018). Managerial challenges of Industry 4.0: An empirically backed research agenda for a nascent field. Review of Managerial Science, 12(3), 803–848. https://doi.org/10. 1007/s11846-018-0283-2

4. Nayernia, H., Bahemia, H., & Papagiannidis, S. (2022). A systematic review of the implementation of industry 4.0 from the organisational perspective. International Journal of Production Research, 60(14), 4365-4396.

5. Gajdzik, B., Grabowska, S., & Saniuk, S. (2021). A theoretical framework for industry 4.0 and its implementation with selected practical schedules. Energies, 14(4), 940.

6. Simetinger, F., & Zhang, Z. (2020). Deriving secondary traits of industry 4.0: A comparative analysis of significant maturity models. Systems Research and Behavioral Science, 1–16. https://doi.org/10.1002/sres.2708

7. Bruna Felippes, Isaac da Silva, Sanderson Barbalho, Tobias Adam, Ina Heine & Robert Schmitt (2022) 3D-CUBE readiness model for industry 4.0: technological, organizational, and process maturity enablers, Production & Manufacturing Research, 10:1, 875-937, DOI:10.1080/21693277.2022.2135628

8. Auza-Santivañez JC, Lopez-Quispe AG, Carías A, Huanca BA, Remón AS, Condo-Gutierrez AR, et al. Improvements in functionality and quality of life after aquatic therapy in stroke survivors. AG Salud 2023;1:15-15.

9. Castillo-González W. Kinesthetic treatment on stiffness, quality of life and functional independence in patients with rheumatoid arthritis. AG Salud 2023;1:20-20.

10. Renteria, C., Gil-Garcia, J.R. & Pardo, T.A. (2019). Toward an enabler-based digital government maturity framework: A preliminary proposal based on theories of change. ICEGOV,Melbourne, VIC, Australia. https://doi.org/10.1145/3326365.3326419

11. Tortorella, G. L., Pradhan, N., Macias de Anda, E., Trevino Martinez, S., Sawhney, R., & Kumar, M. (2020). Designing lean value streams in the fourth industrial revolution era: Proposition of technology-integrated guidelines. International Journal of Production Research, 58(16), 5020– 5033. https://doi.org/10.1080/00207543.2020.1743893

12. Hizam-Hanafiah, M., Soomro, M. A., & Abdullah, N. L. (2020). Industry 4.0 readiness models: a systematic literature review of model dimensions. Information, 11(7), 364.

13. K. Tachibana,T. Furuhashi,M. Shimoda,Y. Kawakami,T. Fukunaga “An application of fuzzy modeling to rowing motion analysis”. IEEE SMC’99 Conference Proceedings. 1999 IEEE International Conference on Systems, Man, and Cybernetics (Cat. No.99CH37028)

14. Makrem Ben Jeddou, Wahiba Bali Kalboussi, Ahmed Dhouibi. « Application de la méthode AHP pour les choix multicritères des fournisseurs ». Revue Marocaine de recherche en management et marketing. N°12, 2015. PP : 60 -71

15. U-Dominic, C. M., Orji, I. J., Okwu, M. O., Mbachu, V. M., & Ayomoh, M. (2021). The Impact of Covid-19 Pandemic on Sustainable Supplier Selection Process. Advancing Industrial Engineering through Teaching, 1-28.

16. Safaei Ghadikolaei, A., Khalili Esbouei, S., & Antucheviciene, J. (2014). Applying fuzzy MCDM for financial performance evaluation of Iranian companies. Technological and Economic Development of Economy, 20(2), 274-291.

17. Caero L, Libertelli J. Relationship between Vigorexia, steroid use, and recreational bodybuilding practice and the effects of the closure of training centers due to the Covid-19 pandemic in young people in Argentina. AG Salud 2023;1:18-18.

18. Ogolodom MP, Ochong AD, Egop EB, Jeremiah CU, Madume AK, Nyenke CU, et al. Knowledge and perception of healthcare workers towards the adoption of artificial intelligence in healthcare service delivery in Nigeria. AG Salud 2023;1:16-16.

19. Kumar, P., Singh, R. K., & Vaish, A. (2017). Suppliers’ green performance evaluation using fuzzy extended ELECTRE approach. Clean Technologies and Environmental Policy, 19, 809-821.

20. Haleh, H., & Hamidi, A. (2011). A fuzzy MCDM model for allocating orders to suppliers in a supply chain under uncertainty over a multi-period time horizon. Expert Systems with Applications, 38(8), 9076-9083.

21. Chen, V. Y., Lien, H. P., Liu, C. H., Liou, J. J., Tzeng, G. H., & Yang, L. S. (2011). Fuzzy MCDM approach for selecting the best environment-watershed plan. Applied soft computing, 11(1), 265-275.

22. Rezaei, J. (2015). Best-worst multi-criteria decision-making method. Omega, 53, 49-57.

23. Ishak Riali,Messaouda Fareh,Hafida Bouarfa . « Fuzzy Probabilistic Ontology Approach ». International Journal on Semantic Web and Information Systems. Issue: 2019,4. PP: 1-20.

24. Othman Bakkali Yedri,Abdelali Slimani,Lotfi El Aachak,Mohamed Bouhorma. «Serious Games Adaptation According to the Learner’s Motivational State». Innovations in Smart Cities Applications Edition 2 Lecture Notes in Intelligent Transportation and Infrastructure. Issue: 2019.PP: 419-436

25. Youness Chaabi,Khadija Lekdioui,Mounia Boumediane. “Semantic Analysis of Conversations and Fuzzy Logic for the Identification of Behavioral Profiles on Facebook Social Network”. International Journal of Emerging Technologies in Learning (iJET). Issue: 2019,07. PP: 144.

26. Tabit, S., & Zoulhi, A. (2021). Road Traffic Management with Fuzzy Logic Approach (No. 5330). EasyChair.

27. TABIT, S., & SOULHI, A. (2022). A MODEL FOR SUPPLIER SELECTION IN MANUFACTURING INDUSTRIES. Journal of Theoretical and Applied Information Technology, 100(20).

28. Alberto Alfonso Aguilar Lasserre,Marina Violeta Lafarja Solabac,Roberto HernandezTorres,Rubén Posada-Gomez,Ulises JuárezMartínez,Gregorio Fernández Lambert. “Expert System for Competences Evaluation 360° Feedback Using Fuzzy Logic”. Mathematical Problems in Engineering. Issue: 2014. PP: 1-18.

29. E. Schmitt,V. Bombardier,L. Wendling. “Improving Fuzzy Rule Classifier by Extracting Suitable Features From Capacities With Respect to the Choquet Integral”. IEEE Transactions on Systems, Man, and Cybernetics, Part B (Cybernetics). Issue: 2008,5. PP: 1195-1206.

30. Hernández-Flórez N. Breaking stereotypes: “a philosophical reflection on women criminals from a gender perspective”. AG Salud 2023;1:17-17.

31. Agnese Marchini,Tullio Facchinetti,Michele Mistri. “F-IND: A framework to design fuzzy indices of environmental conditions”. Ecological Indicators. Issue: 2009,3. PP: 485- 496.

32. Youness Chaabi,Khadija Lekdioui,Mounia Boumediane. “Semantic Analysis of Conversations and Fuzzy Logic for the Identification of Behavioral Profiles on Facebook Social Network”. International Journal of Emerging Technologies in Learning (iJET). Issue: 2019,07. PP: 144

33. GUO-JUN WANG. “COMPARISON OF DEDUCTION THEOREMS IN DIVERSE LOGIC SYSTEMS”. New Mathematics and Natural Computation. Issue: 2005,01. PP: 65- 77

34. Introduction to Fuzzy Logic Fuzzy Sets Shadi T (slidetodoc.com) (consulted on 22.05.2023).

35. Selma Basic “Developing process quality measurement in shipbuilding industry”. Master of Science in Industrial Engineering and Management. September 2019.

36. Hossein Azadi,Mansour Shahvali,Jan van den Berg,Nezamoddin Faghih. “Sustainable rangeland management using a multi-fuzzy model: How to deal with heterogeneous experts’ knowledge”. Journal of Environmental Management. Issue: 2007,2. PP: 236-249

37. Yih-fong TZENG,Fu-chen CHEN. “Optimization of the High-Speed CNC Milling Process Using Two-Phase Parameter Design Strategy by the Taguchi Methods”. JSME International Journal Series C. Issue: 2005,4.

38. Zhong, R., Xu, X., Klotz, E., & Newman, S. T. (2017). Intelligent manufacturing in the context of industry 4.0: A review. Engineering, 3(5), 616–630. https://doi.org/10.1016/J.ENG.2017.05.015

39. Safaei, M., A. Sundararajan, E., Asadi, S., Nilashi, M., Ab Aziz, M. J., Saravanan, M. S., ... & Alsaqour, R. (2022). A Hybrid MCDM Approach Based on Fuzzy-Logic and DEMATEL to Evaluate Adult Obesity. International Journal of Environmental Research and Public Health, 19(23), 15432.

40. Maués, L. M. F., Sá, J. A. S. D., Costa, C. T. D., Kern, A. P., & Duarte, A. A. A. M. (2019). Construction duration predictive model based on factorial analysis and fuzzy logic. Ambiente Construído, 19, 115-133.

FINANCING

The authors did not receive financing for the development of this research.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORSHIP CONTRIBUTION

Conceptualization: Younes Jamouli, Samir Tetouani, Aziz Soulhi.

Research: Younes Jamouli, Samir Tetouani, Aziz Soulhi.

Drafting - original draft: Younes Jamouli, Samir Tetouani.

Writing - proofreading and editing: Younes Jamouli.