doi: 10.56294/dm2024395

ORIGINAL

Predictive analytics on artificial intelligence in supply chain optimization

Análisis predictivo sobre inteligencia artificial en la optimización de la cadena de suministro

Anber Abraheem Shlash Mohammad1,2 ![]() *, Iyad A.A Khanfar3

*, Iyad A.A Khanfar3 ![]() *, Badrea Al Oraini4

*, Badrea Al Oraini4 ![]() *,

Asokan Vasudevan5

*,

Asokan Vasudevan5 ![]() *, Suleiman Ibrahim Mohammad2

*, Suleiman Ibrahim Mohammad2 ![]() *, Zhou Fei7

*, Zhou Fei7 ![]() *

*

1Digital Marketing Department, Faculty of Administrative and Financial Sciences, Petra University, Jordan.

2Research Follower, INTI International University, 71800 Negeri Sembilan, Malaysia.

3Zarqa University, Jordan

4Business Administration Department, College of Business and Economics, Qassim University, Qassim – Saudi Arabia.

5Faculty of Business and Communications, INTI International University. 71800 Negeri Sembilan, Malaysia.

6Shinawatra University. 99 Moo 10, Bangtoey, Samkhok, Pathum Thani, Thailand 12160.

Cite as: Shlash Mohammad AA, A Khanfar IA, Al Oraini B, Vasudevan A, Mohammad SI, Fei Z. Predictive analytics on artificial intelligence in supply chain optimization. Data and Metadata. 2024; 3:395. https://doi.org/10.56294/dm2024395

Submitted: 05-02-2024 Revised: 01-05-2024 Accepted: 30-06-2024 Published: 01-07-2024

Editor: Adrián

Alejandro Vitón Castillo ![]()

ABSTRACT

AI-powered predictive analytics is among the most important ways of optimizing supply chains. This paper on AI-powered predictive analytics will address improving the competitiveness and effectiveness of supply chain operations. Nevertheless, current methods are not always scalable or adaptable to complex supply networks and changing market environments. Therefore, this paper posits that Supply Chain Optimization using Artificial Intelligence (SCO-AI) systems can help with these concerns. SCO-AI employs real-time data analysis and advanced machine learning algorithms which results to reduced response time, enhanced logistics route optimization, improved demand planning as well as real-time inventory control. Thus, the idea herein suggested fits smoothly into existing supply chain frameworks for data-driven decisions that make companies remain agile in ever-changing market dynamics. SCO-AI implementation has seen significant improvements in inventory turnover rate, rates of on-time delivery as well as overall supply chain costs. In this period of high business turbulence, such kind of research builds up the robustness of a given supply chain while at the same time minimizing operational risks by means of simulations and case studies.

Keywords: Predictive Analytics; Artificial Intelligence; Supply Chain Optimization.

RESUMEN

El análisis predictivo basado en inteligencia artificial se encuentra entre las formas más importantes de optimizar las cadenas de suministro. Este documento sobre análisis predictivo impulsado por IA abordará la mejora de la competitividad y la eficacia de las operaciones de la cadena de suministro. Sin embargo, los métodos actuales no siempre son escalables o adaptables a redes de suministro complejas y entornos de mercado cambiantes. Por lo tanto, este artículo plantea que la optimización de la cadena de suministro mediante sistemas de inteligencia artificial (SCO-AI) puede ayudar con estas preocupaciones. SCO-AI emplea análisis de datos en tiempo real y algoritmos avanzados de aprendizaje automático, lo que da como resultado un tiempo de respuesta reducido, una mejor optimización de las rutas logísticas, una mejor planificación de la demanda y un control de inventario en tiempo real. Por lo tanto, la idea aquí sugerida encaja perfectamente en los marcos de cadena de suministro existentes para decisiones basadas en datos que hacen que las empresas sigan siendo ágiles en dinámicas de mercado en constante cambio. La implementación de SCO-AI ha visto mejoras significativas en la tasa de rotación de inventario, las tasas de entrega a tiempo y los costos generales de la cadena de suministro.

En este período de alta turbulencia empresarial, este tipo de investigación fortalece la solidez de una cadena de suministro determinada y, al mismo tiempo, minimiza los riesgos operativos mediante simulaciones y estudios de casos.

Palabras clave: Predictivo; Inteligencia Artificial; Optimización de la Cadena de Suministro.

INTRODUCTION

The changing business environment today requires organizations to have effective supply chain management so as to remain competitive and meet market demands (Al-khawaldah et al., 2022; Aityassine et al., 2021; Cahyono et al., 2023). This paper examines how artificial intelligence driven predictive analytics might shake up the field of supply chain management (Azzam et al., 2023; Al-Alwan et al., 2022; Maheshwari et al., 2021). The traditional approaches towards the optimization of a supply chain may struggle with keeping pace with the fast-changing requirements associated with modern businesses (Hijjawi et al., 2023; Raja et al., 2022). Companies become prone to disruptions and inefficiencies when their models are rigid or they make manual decisions (Azzam et al., 2023a; Azzam et al., 2023b; Niaz, 2022). Along these lines, there is need for exploring new methods that leverage artificial intelligence potential to achieve operational excellence by incorporating predictive analytics (Al-Nawafah et al., 2022; Helo & Hao, 2022).

Contemporary dynamic interconnected environment signifies the beginning of a new era in effective, farsighted strategic decision-making in modern day SCM (Alshawabkeh et al., 2022; Sharma, 2022). The advent of big data powered by predictive analytics and AI has ushered us into this era (AlBrakat et al., 2023a; AlBrakat et al., 2023b; Alolayyan et al., 2022a; Johnson & Nick, 2022). This comprehensive research study looks at whether there is considerable synergy that can be achieved from using predictive analytics systems driven by AI capabilities. The discussion stresses on practical applications, technological intricacies, benefits, barriers, case studies and plans for future improvement. It will serve as an instruction manual to companies who wish to employ predictive analytics for supply chain operations in their businesses (Al-Awamleh et al., 2022; Eleimat et al., 2023; Brintrup et al., 2020).

SCO-AI is a new approach that tries to fix the problems with old supply chain optimization methods (Aityassine et al., 2022; Tirkolaee et al., 2020). SCO-AI enables businesses to harness the power of real-time data analytics and modern machine learning algorithms to make logistical processes simpler than ever before; optimize inventory management; and predict market conditions like never before (Alolayyan et al., 2022b; Attiany et al., 2023; Mahraz et al., 2022). This paper presents the basis for studying how SCO-AI could revolutionize current SCMs in contemporary times through examining current trends and limitations in this area. AI-driven predictive analytics can help improve decision-making, optimally allocate resources among different initiatives and mitigate risks due to a growingly dynamic interconnected marketplace. The contribution for the paper is that SCO-AI, provides scalable solutions to difficult supply chain problems. SCO-AI boosts operational responsiveness and efficiency by improving critical performance indicators. The aim of this study is to illustrate how agility, resilience and competitiveness are affected by SCO-AI using empirical data drawn from cases investigated in this paper. Supply chain management changes promptly but adopting AI-based predictive analytics allows firms stay ahead of this change curve.

Related works

To address these issues, the next section delves into modern approaches and tools for supply chain management. Researchers explore several tactics to improve decision-making, anomaly detection, and demand forecasting. These strategies range from data-driven approaches like LSTM Autoencoder network (LSTM AN) and Fusion-based Machine Learning (F-ML) to the rapidly expanding uses of Big Data Analytics (BDA). The increasing significance of addressing social and environmental concerns in supply chain operations is further shown by the incorporation of sustainability considerations into risk management frameworks, as seen in plithogenic multi-criteria decision-making procedures. Taken as a whole, these publications provide light on how supply chain optimization and risk management are changing.

LSTM Autoencoder network (LSTM AN)

Companies today are confronted with supply chain difficulties, and making the right choices is crucial to their success. To aid in the improvement of supply chain management decision-making, this paper presents two data-driven methods (AL-Zyadat et al., 2022; Rahamneh et al., 2023; Nguyen et al., 2021). These suggestions include an LSTM network-based technique for predicting multivariate time series data and an LSTM AN) based method with a one-class support vector machine algorithm for sales anomalies. The suggested methods will be tested using real-world fashion retail data as well as benchmarking datasets. Based on the findings, it is clear that the LSTM Autoencoder based technique outperforms the LSTM based method proposed in the previous research when it comes to anomaly identification. The suggested approach outperforms competing approaches when tested on a NASA dataset for multivariate time series data.

Fusion-based Machine Learning (F-ML)

Collaboration in the supply chain refers to the interconnected web of organizations and individuals that work together to complete the process (Ali et al., 2022). Organizations in the supply chain can only succeed through collaboration, information sharing, and integration. In Supply Chain Collaboration, the strength and competitiveness of the collaborative process are decision-making based on shared information. It is possible to overcome the challenges and constraints of Supply Chain Collaboration using a platform that is provided by F-ML. The fused ML can provide superior computational capacity and prediction compared to the classically likely data fusion methods. To assess the decision-making process’s tendency to enhance Supply Chain Collaboration efficiency, a machine learning-based model has been suggested.

Big Data Analytics (BDA)

Recently, there has been a surge of interest in using BDA to supply chain management. This is because BDA may be used for many things in SCM, such as analyzing trends, predicting demand, and analyzing consumer behavior (Seyedan & Mafakheri, 2020). To suggest a categorization of these applications, highlight the gaps, and provide ideas for future study, conduct an investigation into the predictive BDA applications in supply chain demand forecasting in this survey. The paper emphasises potential future research directions by drawing attention to the paucity of literature on closed-loop supply chain (CLSC) uses of BDA for demand forecasting.

TOPSIS and Criteria Importance Through Inter-criteria Correlation (CRITIC)

Addressing supply chain sustainability without addressing sustainability concerns may disrupt business. Risk management identifies and analyses loss impacts on commercial, social, and environmental factors, prepares coverage budgets, and develops strategies to maintain supply chain sustainability (Abdel-Basset & Mohamed, 2020). Risk management helps companies make supply chain sustainability choices with confidence. Large organisations need sophisticated but sustaining supply chain risk management solutions since risk is proportional to size. The paper proposes a plithogenic multi-criteria decision-making strategy using TOPSIS and CRITIC. The findings demonstrate the relevance of each sustainable supply chain risk management criteria and the ranking of each of the telecommunications equipment types.

The significance of using modern technologies and approaches to boost operational efficiency, reduce risks, and improve decision-making in supply chain management is highlighted in these connected studies. Finding their way through the maze of contemporary supply chains may be challenging, but these studies provide light on a variety of ways, from data-driven methodologies to sustainability-focused decision-making tactics.

METHOD

Keeping up with the competition in today’s fast-paced corporate world requires optimising supply chains. The use of AI in predictive analytics is a novelty to be explored. However, it may lack scalability and flexibility sometimes. This research introduces SCO-AI systems designed for aligning Artificial Intelligence base with management strategies along the entire value network used within a firm. Transportation travel, forecasting demand, and managing stock are all made more responsive and efficient with the help of SCO-AI; its combination between real time data analytics and sophisticated machine learning solutions achieves this feat. The latter works well within prevailing frameworks so that any information about changes can be obtained from records.

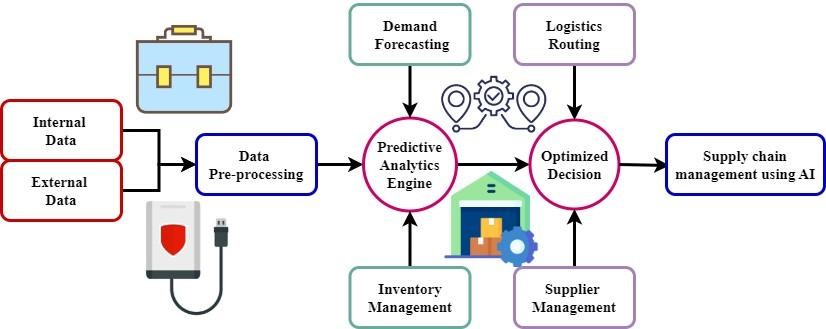

Figure 1. The Block Diagram of SCO-AI

From figure 1 above it is evident that SCO-AI is a complicated system involving several parts moving together simultaneously. The starting points consist of different types internal/external data sources like market trends or weather predictions. These data are then pre-processed prior to being analyzed. The Action takes place in the Prediction Analytics Engine; this is where the advanced machine learning algorithms for demand forecasting and inventory management are located.

These systems provide insights that can be used to optimize supply chain processes based on real-time and historical data. For example, after forecast, optimization and decision module uses this information to enhance logistics route and handling of suppliers. These decisions rely on elaborate artificial intelligence algorithms that adapt to changing dynamics in the supply chain and market. Some of the metrics that determine whether SCO-AI system fits into this process include inventory turnover rates and delivery times within set limits. To achieve quick adaptation and informed decision-making, it integrates easily with current SCM systems.

Figure 2. Risk control using SCO-AI

The suggested approach enhances supply chain risk control capabilities with predictive machine learning and analytics as its foundation. This design is multi-tiered, which allows for easy data collection, processing, modelling, and monitoring in real-time. Complex prediction algorithms detect outliers and possible disturbances by drawing on knowledge from both current and past data sources. The modular nature of the framework makes it easy to incorporate different algorithms that are designed to meet the demands of different supply chains. In addition, it guarantees that timely notifications and actions turn forecast insights into practical tactics. In figure 2, it can see how the AI transformation of data leads to proactive steps for improving supply chain agility, as well as the organized flow of data and making choices within it. Businesses may make their supply chains more resistant to changes in the market and other surprises by integrating machine learning and predictive analytics into a well-defined architectural framework.

![]()

The equation 1 series of terms represented by a(0) and e, where l and m are indices. It appears that these words are being added or combined in the phrase, with p seemingly standing for a parameter. The inclusion of the values in 1/(p-l+1) in the combined terms implies the use of a normalisation or scaling factor.

![]()

In equation 2, the square of the product of the elements in two vectors, a and e, is used as a tool. It seems that the process produces a vector, represented as a E2, where each element is created by multiplying matching elements of aEE and then square the total. While e2 implies that every component of e is squared separately, the notation a0(1) probably denotes the member of the vector a.

ML approaches have recently gained popularity as a means to analyse large datasets, transcending the constraints of more conventional methods. Drawing on literature and bibliometric research, this figure provides an in-depth review of ML applications within the field of SCM. Many different areas of supply chain management make heavy use of ML, including risk management, distribution and transportation, the circular economy, and supplier management in figure 3. Key areas of academic interest, as shown by bibliometric study, include SCM AI problems, performance management, and framework development. The selection of ML approaches for supply chain management, sustainability factors, the direction of ML in supply chain management going forward, and the system needs for ML integration are all under-discussed areas. The findings from these factors may be used to guide managers, provide interesting directions for SCM research, and help practitioners put SCM theory into practice. With this diagram as a guide, it can make way through the ever-changing world of ML in supply chain management.

Figure 3. ML in Supply Chain Management

![]()

The inventory turnover vectors a, e, and y are likely to be involved in the equation given by equation 3. The a0 (l) symbol denotes the l -th element of the vector a in a certain cycle or set of operations. It seems that the phrase between the brackets represents a cumulative or consecutive action, since it sums components from spanning from l to p.

![]()

The timely delivery rates depicted in equation 4 involves vectors a at various iterations, most commonly in computing setting. At iteration p -th, the vector is represented by the term (p). A set of vectors at the l+1-th and l-1-th repetitions, graded by the parameter ∆, is used in the formula on the right-hand side. It is probable that the starting state of vector at the l -th iteration is represented by the term a0(l).

Supply chain failure is now being addressed as a means of enhancing responsiveness, efficiency and flexibility, with SCO-AI using advanced algorithms for machine learning and real-time data analysis. SCO-AI helps in mitigating the operational risks and exploiting possibilities that strengthen supply chain resilience and enhance key performance indicators in today’s uncertain operating environment. Alongside current frameworks, SCO-AI allows organizations to make well informed choices, maximize resource utilization, and succeed in unpredictable surroundings.

RESULTS AND DISCUSSION

The approach suggested had an effect on SCM which discussed how it affects competition, agility of their operations, or robustness while highlighting its advantages/ disadvantages/ implications. These findings provide insights into the practical potential of SCO-AI within supply chains.

Dataset description: here is the dataset link: “Data Analysis: Supply Chain Optimization.” It’s located in a Kaggle repository. It might be worth mentioning that this dataset likely contains comprehensive information concerning supply chain activities to facilitate deep research and optimization programs. Examples of the several aspects of SCM that could be examined include transportation, demand forecasting, logistics as well as inventory management. This dataset may be employed by researchers/practitioners to leverage predictive modeling capabilities to construct scenarios for improving supply chain efficiency, identifying patterns and deriving insights like this article has done; besides it is a good tool for classroom use since it offers both students and working professionals an opportunity to practice what they have learnt when assessing real-life data about supply chains.

Analysis of Total supply chain costs

One way TSCC can be measured is through aggregate supply chain cost (ASCC) as shown in fig. 4 below. TSCC entails summing together costs incurred at each stage throughout the supply chain that includes raw materials up to finished goods or from manufacturing up until shipment along with storage parts.

Figure 4. Total supply chain costs

The overall supply chain costs at various iterations may be determined using the recursive formula ∂l given in equation 5 of the paper.

![]()

Where:

∂l represents the total supply chain costs at iteration l

a denotes a vector that likely encapsulates various cost factors within the supply chain.

∑(j=1)(l-1) a×1(j)calculates the total transformed vectors from the first repetition, indicating cumulative costs up p to the current iteration.

∆(l+1)/∆(l) represents a parameter adjustment that dynamically influences the cost calculation across iterations.

Total supply chain cost calculations may be fine-tuned in a continuous process by tracking the development and improvement of supply chain operations. This technique delivers a thorough insight of the cost dynamics throughout the supply chain by merging real-time data and dynamic parameter modifications.

Analysis of Supply chain resilience

To keep operations running smoothly and reduce risk, supply chain resilience is essential, particularly when dealing with unknowns or interruptions is explain in figure 5.

Figure 5. Supply chain resilience

A model for comprehending and improving supply chain resilience using transformational processes is given by equation 6.

![]()

Where:

az(l) and a Ez denote vectors representing supply chain resilience.

ay(1),a0(2),ap,…,a0(p) symbolize elements of the vector undergoing specific transformations.

The transformational processes indicated by the indices affect the features or qualities of the supply chain, which are captured in vector altered through transformational processes represented by the y indices and 0. The supply chain can withstand challenges and unknowns better if it adopts and improves characteristics like adaptability, redundancy, and flexibility. Important in today’s uncertain and ever-changing economic environments, these equations provide frameworks for measuring and enhancing the financial efficiency and resilience of supply chain operations.

CONCLUSIONS

SCO-AI is a strategy with its positive and negative impacts on supply chain management. It enhances competitiveness, agility as well as robustness. By exposing SCO-AI’s revolutionary potential within real-life supply chains contexts, this research paper provides important future direction for further efforts towards advancing the concept behind SCO-AI. Henceforth, more research should explore ways whereby SCO-AI algorithm could be optimized for different scales involved in supply chains so as to address scalability issues among others like flexibility. Thus, it might be possible to think about new ways of optimizing SCM using SCO-AI together with new technological advancements like Blockchain as well as IoTs (Internet-of-Things). Longitudinal studies examining how adoption of SCO-AI affects performance metrics over an extended period would greatly benefit both scholars and practitioners. Moreover, research on the social and ethical implications of implementing SCO-AI is essential to ensure responsible and fair use of SCM predictive analytics. Therefore, to promote innovation and overcome barriers associated with the uptake of SCO-AI such as risks; academia, firms and governments have to work jointly in this direction. However, there is much room for improvement and further investigation is warranted. Further development of AI-powered predictive analytics for optimization purposes may therefore lead to better supply chains in future. It will make possible safer, more efficient as well as environmentally-friendly supply networks.

Acknowledgment

The Researchers would like to thank the Deanship of Graduate Studies and Scientific Research at Qassim University for financial support (QU-APC-2024-9/1).

BIBLIOGRAPHIC REFERENCES

1. Abdel-Basset, M., & Mohamed, R. A novel plithogenic TOPSIS-CRITIC model for sustainable supply chain risk management. Journal of Cleaner Production, 247, pp. 119586.

2. Aityassine, F., Aldiabat, B., Al-Rjoub, S., Aldaihani, F., Al-Shorman, H., & Al-Hawary, S. The mediating effect of just in time on the relationship between green supply chain management practices and performance in the manufacturing companies. Uncertain Supply Chain Management, 9(4), pp. 1081-1090.

3. Aityassine, F., Soumadi, M., Aldiabat, B., Al-Shorman, H., Akour, I., Alshurideh, M., & Al-Hawary, S. The effect of supply chain resilience on supply chain performance of chemical industrial companies. Uncertain Supply Chain Management, 10(4), pp. 1271-1278.

4. Al-Alwan, M., Al-Nawafah, S., Al-Shorman, H., Khrisat, F., Alathamneh, F., & Al-Hawary, S. The effect of big data on decision quality: Evidence from telecommunication industry. International Journal of Data and Network Science, 6(3), pp. 693-702.

5. Al-Awamleh, H., Alhalalmeh, M., Alatyat, Z., Saraireh, S., Akour, I., Alneimat, S., & Al-Hawary, S. The effect of green supply chain on sustainability: Evidence from the pharmaceutical industry. Uncertain Supply Chain Management, 10(4), pp. 1261-1270.

6. Al-Azzam, M., Al-Alwan, M., Alqahtani, M., Al-Hawary, S., & Alserhan, A. Determinants of behavioral intention to use big data analytics (BDA) on the information and communication technologies (ICT) SMEs in Jordan. Decision Science Letters, 12(3), pp. 605-616.

7. AlBrakat, N., Al-Hawary, S., & Muflih, S. Green supply chain practices and their effects on operational performance: An experimental study in Jordanian private hospitals. Uncertain Supply Chain Management, 11(2), pp. 523-532.

8. AlBrakat, N., Al-Hawary, S., & Muflih, S. The effect of green supply chain on the export performance of the Jordanian pharmaceutical industry. Uncertain Supply Chain Management, 11(2), pp. 613-624.

9. Al-Khawaldah, R., Al-Zoubi, W., Alshaer, S., Almarshad, M., AlShalabi, F., Altahrawi, M., & Al-Hawary, S. Green supply chain management and competitive advantage: The mediating role of organizational ambidexterity. Uncertain Supply Chain Management, 10(3), pp. 961-972.

10. Al-Nawafah, S., Al-Shorman, H., Aityassine, F., Khrisat, F., Hunitie, M., Mohammad, A., & Al-Hawary, S. The effect of supply chain management through social media on competitiveness of the private hospitals in Jordan. Uncertain Supply Chain Management, 10(3), pp. 737-746.

11. Alolayyan, M., Al-Qudah, M., Hunitie, M., Akour, I., Alneimat, S., Al-Hawary, S., & Alshurideh, M. Validating the operational flexibility dimensions in the medical service sectors. Uncertain Supply Chain Management, 10(4), pp. 1397-1404.

12. Alolayyan, M., Al-Rwaidan, R., Hamadneh, S., Ahmad, A., AlHamad, A., Al-Hawary, S., & Alshurideh, M. The mediating role of operational flexibility on the relationship between quality of health information technology and management capability. Uncertain Supply Chain Management, 10(4), pp. 1131-1140.

13. Alshawabkeh, R., Al-Awamleh, H., Alkhawaldeh, M., Kanaan, R., Al-Hawary, S., Mohammad, A., & Alkhawalda, R. The mediating role of supply chain management on the relationship between big data and supply chain performance using SCOR model. Uncertain Supply Chain Management, 10(3), pp. 729-736.

14. Al-Zyadat, A., Alsaraireh, J., Al-Husban, D., Al-Shorman, H., Mohammad, A., Alathamneh, F., & Al-Hawary, S. The effect of industry 4.0 on sustainability of industrial organizations in Jordan. International Journal of Data and Network Science, 6(4), pp. 1437-1446.

15. Attiany, M., Al-Kharabsheh, S., Abed-Qader, M., Al-Hawary, S., Mohammad, A., & Rahamneh, A. Barriers to adopt industry 4.0 in supply chains using interpretive structural modeling. Uncertain Supply Chain Management, 11(1), pp. 299-306.

16. Azzam, I., Alserhan, A., Mohammad, Y., Shamaileh, N., & Al-Hawary, S. Impact of dynamic capabilities on competitive performance: A moderated-mediation model of entrepreneurship orientation and digital leadership. International Journal of Data and Network Science, 7(4), pp. 1949-1962.

17. Azzam, M., Al-Alwan, M., Alqahtani, M., Al-Hawary, S., & Alserhan, A. Determinants of behavioral intention to use big data analytics (BDA) on the information and communication technologies (ICT) SMEs in Jordan. Decision Science Letters, 12(3), pp. 605-616.

18. Brintrup, A., Pak, J., Ratiney, D., Pearce, T., Wichmann, P., Woodall, P., & McFarlane, D. Supply chain data analytics for predicting supplier disruptions: a case study in complex asset manufacturing. International Journal of Production Research, 58(11), pp. 3330-3341.

19. Cahyono, Y., Purwoko, D., Koho, I., Setiani, A., Supendi, S., Setyoko, P., ... & Wijoyo, H. The role of supply chain management practices on competitive advantage and performance of halal agroindustry SMEs. Uncertain Supply Chain Management, 11(1), pp. 153-160.

20. Eleimat, D., Ebbini, M., Aryan, L., & Al-Hawary, S. The effect of big data on financial reporting quality. International Journal of Data and Network Science, 7(4), pp. 1775-1780.

21. Ghazal, T. M., & Alzoubi, H. M. Fusion-based supply chain collaboration using machine learning techniques. Intelligent Automation & Soft Computing, 31(3), pp. 1671-1687.

22. Helo, P., & Hao, Y. Artificial intelligence in operations management and supply chain management: An exploratory case study. Production Planning & Control, 33(16), pp. 1573-1590.

23. Hijjawi, G. S., Eldahamsheh, M. M., Al-Quran, A. Z. F., Almomani, H. M. A., Alhalalmeh, M. I., & Al-Hawary, S. I. S. The mediating effect of digital supply chain management among the relationship between lean management and supply chain operations. International Journal of Economics and Business Research, 26(2), pp. 146-162.

24. Johnson, A., & Nick, A. DATA CHALLENGES AND OPPORTUNITIES IN THE AI ERA: A BIG DATA PERSPECTIVE. EPH-International Journal of Applied Science, 8(4), pp. 5-8.

25. Maheshwari, S., Gautam, P., & Jaggi, C. K. Role of Big Data Analytics in supply chain management: current trends and future perspectives. International Journal of Production Research, 59(6), pp. 1875-1900.

26. Mahraz, M. I., Benabbou, L., & Berrado, A. Machine learning in supply chain management: A systematic literature review. International Journal of Supply and Operations Management, 9(4), pp. 398-416.

27. Nguyen, H. D., Tran, K. P., Thomassey, S., & Hamad, M. Forecasting and Anomaly Detection approaches using LSTM and LSTM Autoencoder techniques with the applications in supply chain management. International Journal of Information Management, 57, pp. 102282.

28. Niaz, M. Revolutionizing Inventory Planning: Harnessing Digital Supply Data through Digitization to Optimize Storage Efficiency Pre-and Post-Pandemic. BULLET: Jurnal Multidisiplin Ilmu, 1(03).

29. Rahamneh, A., Alrawashdeh, S., Bawaneh, A., Alatyat, Z., Mohammad, A., & Al-Hawary, S. The effect of digital supply chain on lean manufacturing: A structural equation modelling approach. Uncertain Supply Chain Management, 11(1), pp. 391-402.

30. Raja Santhi, A., & Muthuswamy, P. Pandemic, war, natural calamities, and sustainability: Industry 4.0 technologies to overcome traditional and contemporary supply chain challenges. Logistics, 6(4), pp. 81.

31. Seyedan, M., & Mafakheri, F. Predictive big data analytics for supply chain demand forecasting: methods, applications, and research opportunities. J Big Data, 7, pp. 53.

32. Sharma, A. Managing Complex Supply Chains: Lessons from Military Logistics. International Journal of Supply Chain Management, 12(6), pp. 26-38.

33. Tirkolaee, E. B., Mardani, A., Dashtian, Z., Soltani, M., & Weber, G. W. A novel hybrid method using fuzzy decision making and multi-objective programming for sustainable-reliable supplier selection in two-echelon supply chain design. Journal of Cleaner Production, 250, pp. 119517.

FINANCING

With financial support from the Deanship of Graduate Studies and Scientific Research at Qassim University (QU-APC-2024-9/1).

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORSHIP CONTRIBUTION

Conceptualization: Anber Abraheem Shlash Mohammad, Iyad A.A Khanfar, Suleiman Ibrahim Mohammad.

Data curation: Badrea Al Oraini, Zhou Fei.

Formal analysis: Badrea Al Oraini, Zhou Fei.

Research: Anber Abraheem Shlash Mohammad, Suleiman Ibrahim Mohammad.

Methodology: Anber Abraheem Shlash Mohammad, Asokan Vasudevan, Suleiman Ibrahim Mohammad.

Drafting - original draft: Badrea Al Oraini, Zhou Fei.

Writing - proofreading and editing: Anber Abraheem Shlash Mohammad, Suleiman Ibrahim Mohammad.