doi: 10.56294/dm2024373

ORIGINAL

Blockchain Technology for tracking and tracing containers: model and conception

Blockchain para el seguimiento y rastreo de contenedores: modelo y concepción

Safia Nasih1 ![]() *, Sara Arezki1

*, Sara Arezki1 ![]() *, Taoufiq Gadi1

*, Taoufiq Gadi1 ![]() *

*

1Faculty of Sciences and techniques, Computer science department. Settat, Morroco.

Cite as: Nasih S, Arezki S, Gadi T. Blockchain Technology for tracking and tracing containers: model and conception. Data and Metadata. 2024; 3:373. https://doi.org/10.56294/dm2024373

Submitted: 25-01-2024 Revised: 29-04-2024 Accepted: 07-07-2024 Published: 08-07-2024

Editor:

Adrián Alejandro Vitón Castillo ![]()

ABSTRACT

The maritime industry has increasingly integrated advanced technologies such as AI, Blockchain, Big Data, and IoT, transforming traditional port operations into smart facilities aimed at enhancing global trade competitiveness. A particular focus has been on improving tracking and tracing services, with Blockchain technology emerging as pivotal for ensuring data integrity, transparency, and traceability across supply chains. This article proposes a blockchain-based tracking and tracing system model tailored for monitoring containers in Moroccan ports. Utilizing the Unified Modeling Language (UML), the model seeks to optimize resource allocation and boost stakeholder satisfaction through detailed diagrams and functional data requirements depiction. Despite challenges such as IoT terminal platform connectivity and operator resitance, successful implementation was achieved, establishing a foundational framework for a comprehensive container monitoring system. This model provides valuable insights for supply chain professionals and scholars interested in item tracking, aiming to integrate Blockchain with technologies like RFID, GPS, RTLS, QR Codes, BLE, and IoT sensors to enhance port operation efficiency and container management effectiveness. By leveraging these integrated technologies, ports can further improve operational efficiency and ensure accurate traceability of containers throughout the supply chain, contributing to overall trade facilitation and economic growth.

Keywords: Blockchain Technology; Tracking and Tracing; Container; Smart Port; Model.

RESUMEN

La industria marítima ha integrado cada vez más tecnologías avanzadas como IA, Blockchain, Big Data e IoT, transformando las operaciones portuarias tradicionales en instalaciones inteligentes destinadas a mejorar la competitividad del comercio mundial. Un enfoque particular ha sido la mejora de los servicios de seguimiento y localización, con la tecnología Blockchain emergiendo como fundamental para garantizar la integridad de los datos, la transparencia y la trazabilidad a través de las cadenas de suministro. Este artículo propone un modelo de sistema de seguimiento y rastreo basado en blockchain adaptado a la supervisión de contenedores en los puertos marroquíes. Utilizando el Lenguaje Unificado de Modelado (UML), el modelo busca optimizar la asignación de recursos y aumentar la satisfacción de las partes interesadas a través de diagramas detallados y la representación de requisitos de datos funcionales. A pesar de dificultades como la conectividad de la plataforma de terminales IoT y la resistencia de los operadores, se logró una implementación satisfactoria, estableciendo un marco fundacional para un sistema integral de supervisión de contenedores. Este modelo proporciona información valiosa para los profesionales de la cadena de suministro y los académicos interesados en el seguimiento de artículos, con el objetivo de integrar Blockchain con tecnologías como RFID, GPS, RTLS, códigos QR, BLE y sensores IoT para mejorar la eficiencia de las operaciones portuarias y la eficacia de la gestión de contenedores. Al aprovechar estas tecnologías integradas, los puertos pueden mejorar aún más la eficiencia operativa y garantizar la trazabilidad precisa de los contenedores a lo largo de la cadena de

suministro, contribuyendo a la facilitación del comercio en general y al crecimiento económico.

Palabras clave: Tecnología Blockchain; Seguimiento y Rastreo; Contenedor; Puerto Inteligente; Modelo.

INTRODUCTION

The maritime industry has undergone significant advancements in recent decades by adopting cutting- edge technologies like Artificial Intelligence,(1) Blockchain, Big Data,(2) and the Internet of Things.(3) This technological revolution has led to the transformation of many ports into smart facilities, driven by the growing recognition of technology’s role in maintaining competitiveness in global trade.(4)

Within container terminals, numerous operations have transitioned from traditional to intelligent services through digitalization. Despite this progress, there remains ample opportunity for further research, particularly in enhancing tracking and tracing services. This need was underscored in recent dies(5,6,7) that sought to identify developed and enhanced services using these disruptive technologies over the past five years.

On one hand, traceability, as defined by the United Nations Global Compact and Business for Social Responsibility involves the ability to trace the history, distribution, location, and application of products, parts, and materials. This ensures the credibility of sustainability claims across various domains such as human rights, health, information security, environmental conservation, and anti- corruption efforts.(8)

On the other hand, Blockchain technology emerges as a groundbreaking solution for asset tracking, guaranteeing security and data integrity within the supply chain. Given the inherent challenges of visibility and transparency in product flows, Blockchain-based traceability offers a secure platform for information sharing, enabling enhanced product quality monitoring, operational control, real-time data acquisition, and improved transparency and visibility throughout the supply chain.(9)

This study aims to present a use case model for a Blockchain-based tracking and tracing system designed to monitor containers within Moroccan ports. The specific objectives are to improve the effectiveness and clarity of container monitoring, enhance stakeholder satisfaction by providing accurate and real-time data on container status, and optimize resource allocation within port operations. Additionally, the study seeks to address challenges related to IoT terminal platform connectivity and operator reluctance to adopt Blockchain technology. Ultimately, the goal is to provide a foundational framework for professionals and researchers in supply chain management to develop comprehensive container monitoring systems. By leveraging the Unified Modeling Language (UML), this study illustrates the system’s functional and data requirements, offering valuable insights into the implementation of Blockchain technology in supply chain tracking and tracing.

Tracking and tracing

Blockchain technology serves different functions, both inside and outside of port operations, including tracking and tracing procedures, preserving transaction histories, and facilitating stakeholder communications. Chang et al.(10), for instance, presented a blockchain-based system that makes use of smart contracts to track data and promote network collaboration among port participants. From the perspective of operations management, this research offers conceptual guidelines for the design and implementation of practical business systems that also improve efficiency. Supply chain managers may monitor the status of cash flows and logistics using the suggested blockchain-based architecture with smart contracts, and then create appropriate plans to reduce inefficiencies. Transparent tracking can aid in real-time control of the supply chain, as proposed by Chang et al. Additionally, using digital currency as an alternative payment option might shorten the payment lead time.

In another study, researchers(11) created a system specifically designed to track and monitor data related to COVID-19, involving the use of Ethereum smart contracts and oracles to create a blockchain system that tracks data pertaining to the quantity of new cases, fatalities, and recovered instances. This study presents methods that delineate the relationships among stakeholders in the network and provided further information on the expenses incurred by security analysis.

Furthermore, a systemic literature review focused on Blockchain applications in supply chain management identified five case studies in which technologies like Blockchain are not used frequently, one of them being tracking and tracing. This highlights the significant potential and need for Blockchain technology in improving traceability within supply chains.(12)

The tracking and tracing operation involves techniques and technologies that help identify the location and movement of products or goods in the trade process. The complexity of operations in such environments requires robust and effective tracking systems to ensure smooth transitions, reduce downtime, and optimize resource allocation. Here are some of the most important approaches and technologies implemented in tracking and tracking containers in port environments:

RFID: Radiofrequency identification, or RFID, is a key technology in the field of tracking containers and goods across various points in the logistic process. This technology is mainly divided into two types of labels, each tailored to specific applications depending on the needs of scope and interaction with read systems. Active RFID tags are useful for real-time container tracking. Fixed on them, they have an extended range, allowing them to communicate effectively with porch readers or portable devices. This feature makes them ideal for logistics environments where instant and precise location of goods is essential for managing product flows(13,14). On the other hand, passive RFID tags, which operate at a shorter range, are mainly used for the identification of containers when they cross various control points. These labels do not require an internal power source, which makes them less expensive and more suitable for applications where goods need to be scanned over short distances, such as mounting chains or when switching to specific checkpoints. Together, these two types of RFID labels provide a comprehensive solution for container management and tracking.(15)

GPS: the global positioning system,(16) or GPS, has become an essential tool for tracking the movements and precise positioning of handling equipment and transport vehicles such as trucks. The use of GPS tracking enables port operators to monitor the location of various equipment and vehicles in the port in real-time. This continuous tracking capability is crucial to optimizing logistics processes, ensuring that container handling equipment is used efficiently and that the containers are stored or transported to the right place without unnecessary delays. By minimizing travel times and improving the ordering of loading and unloading operations, GPS contributes directly to reduced operating costs and improved overall productivity. In addition, this technology facilitates better resource allocation and better management of port storage spaces, thereby more effectively responding to complex logistics requirements and increasing customer satisfaction.

Real-time Localization Systems (RTLSs) are key technology for improving asset management and optimizing operations in port areas and other logistics facilities. Among the various RTLS technologies, ultra-wide bandwidth (UWB) is distinguished by its ability to locate containers and handling equipment in the port facility with extreme accuracy. This accuracy enables almost instantaneous visualization of the exact position of assets, thus facilitating better planning of storage and recovery operations, and helping to minimize waiting times and delays, thereby optimizing the overall efficiency of logistics processes.(16)

In addition, Wi-Fi-based RTLSs offer an alternative solution that utilizes the existing wi-fi infrastructure to locate property. Although this method is generally less precise than UWB, it has the advantage of being able to be deployed quickly and at a lower cost, taking advantage of existing network equipment. This approach is useful for installations that require extended coverage without the investment required for more sophisticated systems such as the UWB.

QR Codes and Barcodes

In the port sector, barcodes and QR codes are needed to improve container management. Employees use mobile scanners to read these codes that are directly connected to detailed databases. These databases contain essential information such as the contents of the containers, their origin, destination and specific handling instructions. By reducing handling errors and accelerating the verification and transfer processes of goods, this technology significantly simplifies logistics, thus ensuring smooth and efficient management of product flows across the port.(17,18)

Internet of things

The development of the Internet of Things (IoT) improves port infrastructure and container management by integrating IoT sensors. These sensors, placed in containers or in handling devices, play an essential role in monitoring environmental variables such as temperature or humidity. It is essential to ensure the integrity of sensitive goods. In addition, these IoT sensors offer the ability to give alarms for preventive maintenance or to report any operational malfunction, which reduces the risk of failures and improves equipment maintenance. The implementation of IoT in port operations ensures proactive resource management and achieves a significant improvement in operational efficiency.(1,19)

By combining these technologies, ports have the ability to manage their resources more dynamically and responsively, which improves logistics operations fluidity and workflow management. By incorporating RTLS into operational strategies, it is possible to improve asset localization accuracy while improving productivity and reducing operating costs.

Container tracking and tracing

Containerization is an intermodal freight transport system that uses shipping containers. These containers have standard dimensions, and can be loaded, unloaded, stacked, transported effectively over large distances, and converted between modes of transportation, such as container ships or rail transport. Containers are assigned numbers according to an international standard that allows them to automatically tracked. Containerization also lowers shipment time while minimizing damage and theft costs. Furthermore, it eliminates human sorting of most goods and the requirement for warehousing.

Tracing can lower container transportation, administrative, and communication expenses. All stakeholders (actors in ports and customs) will have mutual access to supply chain data. However, Munuzuri&al(20) presents a system that includes supply chain containers linked to roads, trains, and vessels. This concept is built on an intermodal terminal with rail and road access that is linked to the sea via an inland canal. The primary components of the system proposed by Manuzuri&al(20) are the following: (1) Sensors for tracking and tracing containers on trains. Instead of using individual GPS links for each container, they communicate with a central unit within the locomotive, resulting in significant cost and energy savings. Other sensors are also used to detect any unusual activity inside the container, such as an opening or an unexpected temperature rise; (2) Real-time data can help plan drayage fleets used to collect and transport containers. An automated signal box and a custom-built planning unit make it easier for trains to access the port terminal; (3) A smart navigation system is used to navigate ships, organize events and crossings, manage light buoys, and detect timing errors.

According to Liu&Takakuwa,(21) operational activities at the Nabeta Pier container terminal in Nagoya, Japan, are simulated to assess processing time and identify bottlenecks in operational flows. Real-time tracking data is collected electronically from information systems. The study concludes that simulation- derived information is valuable for analyzing portal operation performance. Meanwhile, Madlenak et al.(22) focuses on container traceability and control, utilizing RFID technology for automatic data capture. The authors employed a web application to track and measure container dwell times at a specified center, identifying conditions for RFID technology implementation in container monitoring and identification. This represents a significant step towards enhancing identification and visibility across the entire logistics chain. Additionally, (6) proposes an effective container transport security system, incorporating subsystems like real-time container tracking and intrusion monitoring. The paper hypothesizes that integrating advanced software and hardware solutions can cost-effectively reduce expenses in Intermodal and Maritime Transport Management through an Electronic Container Tracking System. The findings from these studies hold practical value for practitioners, aiding in enhancing competitiveness for carriers, forwarders, logistics, and IT companies.

Blockchain technology

The term “Blockchain” emerged in November 2008 in an essay published on peer-to-peer electronic cash systems. This document was shared on a mailing list of American cryptographers by one or more individuals using the pseudonym Satoshi Nakamoto(23). The objective of this paper was to address the issue of double spending, which arises with the advent of cryptocurrencies. Double spending refers to the challenge of securely verifying the sender’s intention to transfer values and preventing the duplication of assets at their disposal. This issue does not arise with cash payments, as the transfer or possession proves ownership of the transferred value. The outcome of this article was that Satoshi Nakamoto and his team created an open platform called Bitcoin, where members may exchange the currency named “Bitcoin”. Otherwise, Blockchain technology is involved in many sectors, such us Supply chain,(10,24) Finance,(25,26) Healthcare,(27,28) Education(29) and Trade(30), etc.

Blockchain characteristics:

Immutability(28,31)emphasizing the significance of collecting, managing, and sharing information. Technological advancements have facilitated the transformation of healthcare data into electronic health records (EHRs

In blockchain, immutability refers to permanent, unchangeable data. Data stored on a blockchain system can never be altered, modified or deleted once it has been recorded, since it is stored in many different locations, so modifying or deleting a copy of the data in one or a limited number of places presents no threat.

To ensure the authenticity and integrity of the data, the information is carefully documented and protected from any possible modification. Hence, the data must be precise. From a pragmatic perspective, it is crucial to offer a function or module that allows for the storing and validation of the data’s genuineness. This can be accomplished by identifying any inaccurate data that originates from the data source.

Transparency

Blockchain is based on a distributed structure, with transactions and data stored in identical copies in multiple locations. All participants in the network are authorized to access the same information at the same time, creating complete transparency. Supply chain transparency refers to the extent to which supply chain stakeholders have a common understanding and access to product and process information without loss, noise, delay and distortion.(32) Transparency is closely associated with traceability and visibility.(33) Blockchain technology can promote transparency in supply chains. It is increasingly being studied, with a focus on transparency-enhancing system structures and architectures.

Decentralization(28)emphasizing the significance of collecting, managing, and sharing information. Technological advancements have facilitated the transformation of healthcare data into electronic health records (EHRs

Based on distributed and decentralized network of nodes, the structure of the Blockchain network is built on a system with no central control. Nodes are responsible of validation and verification phase, this makes it difficult to model, maintain control or impose a transaction without consensus among the nodes. One of its features is fault management, in other words, the absence of a central point of failure (SPOF), which makes for a fault-tolerant, stable system, resistant to attacks, symmetrically secure, with authority granted to its nodes equally. In addition, maintenance and updating by the nodes must respect consistency and integrity within the network of nodes, so the establishment of a consensus algorithm is mandatory.

How Blockchain technology works and Consensus

Blockchain is an immutable ledger; once a transaction is recorded, it is difficult to change or delete it. Blockchain technology operates as a network of nodes where transactions are disseminated and stored in every node’s ledger copy. Verification of communications between nodes involves the participation of nodes in this process. Each node has two keys: a public key and a private key. Transactions are authenticated using these two keys and then validated. When a transaction is submitted, it is verified and validated by miners, then included in a block, which is subsequently added to the chain of blocks known as the blockchain. This process is secured by cryptographic methods and is based on consensus.(34)

Consensus is the method by which a collective of nodes reaches a mutual understanding on the accuracy and sequence of transactions included in the blocks. The objective of consensus is to establish agreement on the sequence and verify the accuracy of the collection of transactions that make up the block. It ensures a certain sequence of transactions and verifies the block of transactions within a network of nodes. There exists a variety of consensus algorithms that can be applied to different use cases. The following lines highlight the most commonly used consensus mechanisms:

Proof of work(35): this consensus technique relies on the use of computing resources to propose a value that is approved by the network. In this consensus, miners have to solve complex mathematical puzzles using all their computing power. Whoever solves the problem first receives the right to add a reward block to the chain. However, the process is not that simple. A puzzle can only be solved by trial and error. Moreover, the level of complexity of the puzzle increases with the speed at which the blocks are extracted. It therefore becomes mandatory to create a new block within a certain period to cope with the level of difficulty. This process consumes a lot of energy compared with other algorithms. Proof of work is implemented in Bitcoin and other cryptocurrencies. This approach has proven effective in mitigating Sybil attacks.

Proof of stake(32): this approach relies on the principle that a node or user holds a significant percentage of ownership in the system. Another important consideration is the notion of coin age, which is calculated based on the length of time and the number of coins that have not been used. In this model, the likelihood of suggesting and validating the next block is directly linked to the age of the currency. In this algorithm, validating nodes are not called ‘miners’, but rather ‘validators. They can create a block for everyone, which saves energy and time. However, to become a validator, they have to invest a certain amount of money. In addition, unlike PoW, validators have the privilege of collecting their transaction fees in this algorithm, as there is no reward system in this consensus model.

Overall, this has encouraged brands like Ethereum to move their model from PoW to PoS in their Ethereum 2.0 update. While PoS has solved many of the problems associated with PoW, there are still many challenges in the market.

METHODS

A study conducted at the CASA Port container terminal generated a list of problems encountered by key supply chain participants at the port. In this context, we interviewed experts from the Moroccan port operator. These maritime operators oversee container handling, which encompasses storage, container reception, delivery to respective customers, and acting as intermediaries between the shipowner (handling intercontinental sea transport of containers), the harbor master’s office, and customers.

The study introduces a model for tracking container movement from their arrival on ships until departure. The project’s goal is to develop a system capable of tracking containers within the portal region and facilitating their transportation from suppliers to consumers outside the portal territory, utilizing Internet of Things (IoT), blockchain, and RFID sensors.

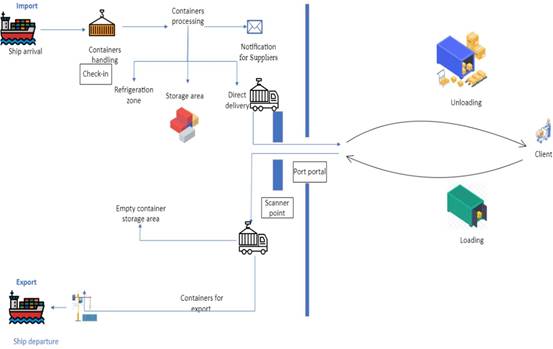

Figure 1 illustrates various phases of container handling, from initial arrival at the port to placement in the parking zone or delivery to carriers within the Casa Port terminal. It also depicts the containers’ journey beyond the port until they are returned by carriers, suppliers, and consumers. Before a vessel’s arrival, a file named BAPLIE is transmitted to both the Port Authority and the operator responsible for container handling. The operator then arranges the necessary crew and logistics for container handling and notifies the client upon their containers’ arrival. Containers awaiting delivery are categorized into three types: those containers directly delivered to carriers such as petroleum products liquid products, containers handling pharmaceuticals or perishable goods requiring controlled temperatures (mostly refrigerated shipping containers or “reefer’s containers”), which are directed to a refrigerated area with electrical outlets, and containers without specific delivery schedules, which are stored until carriers arrive.

Figure 1. The tracking and tracing use case in the casa port container terminal TCE

Outside the port, there are two key players: Carriers and Customers. Customers receive notification messages or calls from the operator, which then informs the carrier to unload or load the container truck.

Carriers are responsible for transporting containers to suppliers and subsequently to the client. Upon arriving at the port entrance, carriers present necessary documents to the authorities, collect the containers, undergo scanning for goods and container control, and then leave the port. The carrier delivers containers to customers, who unload them with the products for the end customer. After unloading, the containers may be returned to the supplier or kept for other transactions. Container security is the responsibility of the supplier and the carrier, with carriers paying insurance for container delivery and suppliers handling customs duties if they retain the containers.

Containers are categorized as export-bound or returned empty to the port, stored in the empty container zone. Ports, including CASA PORT, manage container data such as location, BIC code, ship arrival information, and customer details through information systems. Common problems related to containers include delays caused by forwarding agents, container damage from accidents, and inefficiencies in traffic management within the port area.

Addressing these issues requires robust container tracking systems integrated with technologies like Blockchain. This entails using sensors or similar tech for data collection, an IoT platform for network control and data gathering, and Blockchain for decentralized data processing. Efficient container tracking helps prevent delays, damages, and traffic issues, enabling timely interventions when needed.

IMPLEMENTING BCT IN THE TRACKING AND TRACING OPERATION

Modeling of the tracking and tracing use case

Tracking and tracing operations are crucial in ports and terminals, as they enable the management of the vast volume of products and containers passing through. In the interview conducted for this study, it was found that the operator’s information system effectively handles the movement and placement data of containers within the port area. However, once the carrier leaves the port premises, the container’s location becomes uncertain for both operators and clients, and sometimes even the supplier cannot ascertain the whereabouts of their products. This lack of real-time data affects several stakeholders involved in the operation.

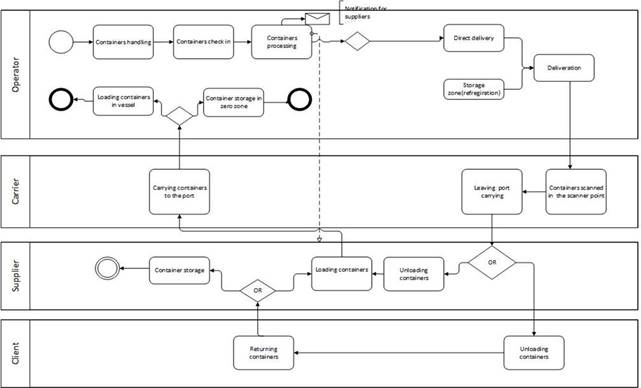

The workflow below illustrates the container business process as they enter and exit the terminal. This process involves four key players: the operator, the carrier, the supplier, and the client, with the shipowner also playing a role. However, our analysis focuses mainly on data provided by the operator, as it encompasses essential information obtained from the shipowner.

Figure 2. BPMN process model for container tracking at port level

Figure 2 describes the movement of containers from the arrival of the ship carrying them to their departure or storage in the container storage area. The process is divided into two parts: in the hinterland and outside the port area. Figure 1 shows the main actors in the container delivery process:

(1) The terminal operator: When the ship approaches the port, it sends a message to the authorities represented by the ANP, which is responsible for informing the terminal operator or operators concerned by the containers carried by the ship. The containers are handled as soon as they arrive at the port and the operator sends the agents to unload, handle and check the containers;

(2) The carrier: Some of the incidents discussed in this thesis, concerning containers, were found during their handling by carriers, either in the terminal or on their way to the customer. One of the advantages of the system proposed in this work is to be able to follow the containers in this part to get help as soon as possible (in case of accident, theft or damage). The blockchain network is built on transactions between all nodes. Nodes fulfill one of the following roles: (i)The client can only examine the container’s processing status; (ii) A member of the organization who can add a block or a transaction to a block, track a container, and so on.

(3) The Orderer is an organizational member who orders transactions and adds them to the block.

(4) Finally, the Endorser evaluates and certifies the system.

Transactions exchanged in the network, concern container updates. Each transaction pertains to a single container, and the nature of the transaction is either an addition, an update of the processing status, a position update, a temperature update, or finally the tracking of the container.

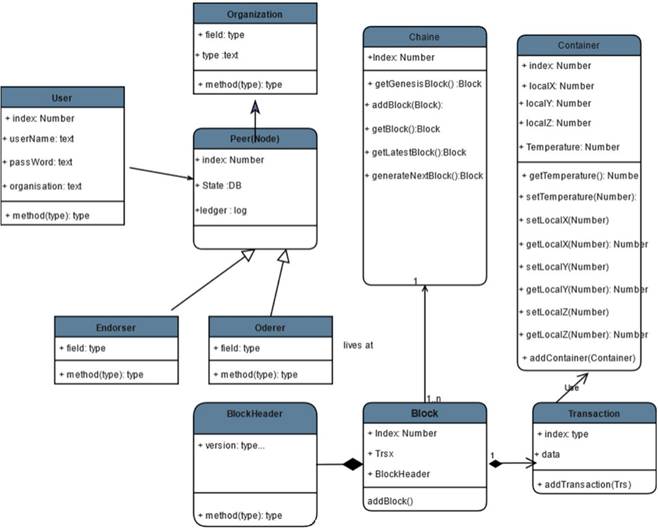

Class diagram

This UML class diagram captures the system elements and interactions within a blockchain system. It highlights the roles of users, organizations, nodes, and blocks, as well as the processes of block creation, transaction management, and data handling. In the same diagram, the relationship between the data structure of blockchain technology and the tracking and tracing of containers. The relationships between these classes illustrate how data integrity and network functionality are maintained in the. blockchain environment.

In this system, the user identifies himself either as a customer or an internal user belonging to a specific organization (here the organization presents one of the port’s stakeholders: the port operator, the shipowner, the harbor master’s office, etc.). A user can identify himself with his username and password using the function authenticate (text, text). Each user belonging to an organization constitutes a node. Each node has a copy of the ledger where the history of all transactions carried out is recorded, and a state of the proposed system’s blockchain in the form of a database showing the latest state of the data.

Figure 3. The class diagram for the tracking and tracing process implemented with the blockchain data structure

The chain consists of several chained blocks each block is bound to a block Header. each block is made up of a list of transactions. In addition, the transaction contains the data of the container concerned. The container class is characterized by the parameters of identification, localization, and temperature. In other hand, each transaction concerns a specific container. The nature of the transaction is either an addition, an update of the container processing status, the location, the temperature, or finally the tracking of the container.

Sequence diagram

The sequence diagrams provide a comprehensive representation of the essential operations within a blockchain system, with a particular focus on data insertion, monitoring and modification. Each figure illustrates the interrelationships between different components, showing how the system ensures data integrity, correct sequencing, validation and eventual insertion into the blockchain.

Authentication

In order to use the application, users must first complete the registration process. After registration, users will need to authenticate themselves by selecting either the client or peer access type. The user’s accessible functions can be specified based on the type of access granted.

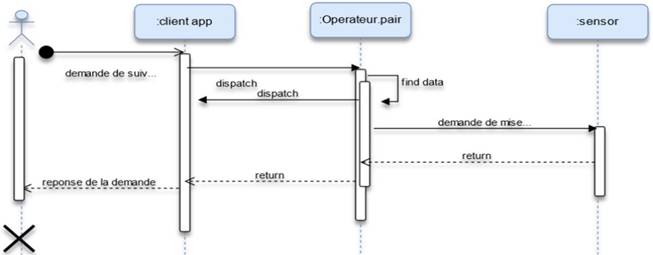

Searching/tracking a container

In this diagram, This sequence diagram illustrates the tracking process within a blockchain system, detailing the interaction between a client application, operator pair, and a sensor device.

Figure 4. Authentification sequence diagram

Figure 5. Tracking container sequence diagram

This diagram shows the flow of information between a client application, an operator pair, and a sensor, demonstrating how data is tracked and managed within the system.

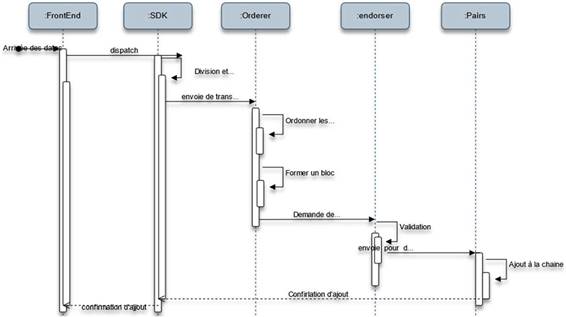

Adding a container:

This sequence diagram outlines the process of adding data to a blockchain system, showing the interaction between different components. Adding data in this diagram is controlled by the blockchain protocols for validation and verification.

The diagram effectively captures the sequence of actions required to add data to a blockchain, highlighting the roles of the FrontEnd, SDK, Orderer, Endorser, and Pairs in ensuring the data is correctly processed and added to the blockchain.

Implementation

To explain the context of the implementation of this study’s proposition, we propose this simplified layered diagram. As it is clear, the proposition implementation is limited to the application Layer. In the next lines, we detail each layer with its function and role.

Figure 6. Container add sequence diagram

Figure 7. Blockchain Layers for tracking and tracing process

In this figure, the architecture of the proposed model is organized in four layers. This structure is taken from the IOT architecture:

(1) Device layer: Consists of devices connected to the system. Smart devices are products or assets that integrate sensors, processors, actuators and the ability to transmit data over the Internet. They can collect data from their environment and share it with operators, users, other smart devices and applications connected to the system. Smart devices can incorporate different types of sensors to collect data from their environment. In this model, we use position sensors attached to containers to determine their position, whether inside or outside the port. The sensors send the position data to the network layer.

(2) Network layer: The network layer is built on top of the IOT network. The network layer is responsible for encapsulating and building packets, then transmitting them from source to destination. To accumulate and manage all data streams, data collected from RFID devices is stored in packets in the IOT network using an IOT platform.

(3) Data layer: Data layer is a layer where data is processed, analysed and then sent to the elements concerned. The IOT platform belongs to the data layer in most applications. In our proposal, blockchain technology will also be integrated in this layer, its role is to transform data formatted by IOT platform into data blocks, validated then added to the chain of blocks.

(4) Application layer: The application layer is responsible for ensuring effective communication with external applications. In this proposal, a front-end application is implemented with a smart contract to the application layer, this smart contract is sent to the user of the system depending on the need, and the user of the system gets his copy of blockchain data that is constantly updated.

Tracking and tracing container algorithms:

As mentioned above, the transactions exchanged are related to containers. Each transaction is associated with a specific container. To streamline operations, we will create a smart contract for adding and updating the processing status, location, temperature, and tracking of the container. The proposal consists of a blockchain network configured with nodes from various organizations in the supply chain (manufacturers, transporters, distributors, etc.). The blockchain network is built on transactions between all the nodes, with each node assuming one of the following roles: Customer, who can view only the processing status of the container; Organization Member, who can add a block, a transaction to a block, or track a container; Orderer, an organization member responsible for ordering transactions and adding them to the block; and Endorser, who verifies and validates the system.

RESULTS AND DISCUSSION

The study conducted at the CASA Port container terminal highlighted several critical issues faced by key stakeholders in the port supply chain. Maritime operators, who handle container operations, pointed out challenges in storage management, container reception, and delivery to clients. Significant friction points were noted in the interactions between shipowners, the port authority, and clients.

The implementation of a blockchain-based tracking and tracing system demonstrated significant improvements in the transparency and reliability of port operations. The proposed model enabled comprehensive tracking of container movements from their arrival on a ship to their departure, offering enhanced visibility and optimized resource management. Blockchain technology ensured the integrity of data throughout the supply chain, effectively mitigating risks of fraud and errors.

The literature extensively supports the findings of this study, highlighting the transformative potential of blockchain technology in supply chain management. For instance, Marbouh et al.(11) and Truong et al.(36) emphasize the role of blockchain in enhancing transparency and security in IoT systems, which aligns with the observed improvements in data integrity and operational transparency at CASA Port.

The adoption of blockchain technology for container tracking presents several significant advantages. Firstly, as noted by Blossey et al.(37), blockchain’s decentralized nature ensures that all stakeholders can access accurate and real-time information. This increased transparency leads to better coordination among supply chain actors and a reduction in operational inefficiencies.

Secondly, the ability to track the complete history of a container, from origin to final destination, is crucial for regulatory compliance and safety standards. This aligns with the findings of Chang et al.(25) who highlighted blockchain’s capability to re-engineer supply chain processes and ensure reliable tracking through smart contracts.

Thirdly, the assurance of data integrity and the ability to resolve disputes quickly, as evidenced by the literature, bolster stakeholder confidence. Lee et al.(19) and Hieketa(3) discuss how blockchain can enhance trust in IoT and supply chain systems by providing a tamper-proof record of transactions.

Finally, despite initial challenges in integrating IoT platforms and overcoming operator reluctance, solutions were effectively implemented. This mirrors the experiences documented by Madleňák et al.(22) and Ettaloui et al.(28)emphasizing the significance of collecting, managing, and sharing information. Technological advancements have facilitated the transformation of healthcare data into electronic health records (EHRs, who discuss the practical challenges and solutions in implementing blockchain technology in logistics and health records management.

CONCLUSIONS

This article presents a conceptual model for addressing the problem of tracking and tracing containers in a port terminal. Our study focused on containers managed by carriers, tracking their location from unloading to loading or storage, both within and outside the hinterland.

Existing literature suggests the use of blockchain for port access policies, which decentralizes trust but requires policy updates to be managed by owners, a mechanism that does not scale well with IoT systems. According to prior research, blockchain can enhance the scalability of policy management by shifting policy update operations to the blockchain backend via smart contracts. This approach leverages blockchain technology to make IoT systems more scalable.

Combining IoT with blockchain offers significant advantages, such as autonomous transactions through smart contracts. This synergy between IoT and blockchain is a topic of intense discussion in both the industry and research communities. Our proposal serves as a practical use case demonstrating the benefits of this combination, particularly in the supply chain context. It highlights the potential of these technologies to address challenges and opens new opportunities for further research.

REFERENCES

1. Xiao G, Yang D, Xu L, Li J, Jiang Z. The Application of Artificial Intelligence Technology in Shipping: A Bibliometric Review. J Mar Sci Eng 2024;12:624. https://doi.org/10.3390/jmse12040624.

2. Munim ZH, Dushenko M, Jimenez VJ, Shakil MH, Imset M. Big data and artificial intelligence in the maritime industry: a bibliometric review and future research directions. Marit Policy Manag 2020;47:577–97. https://doi.org/10.1080/03088839.2020.1788731.

3. Hiekata K, Wanaka S, Mitsuyuki T, Ueno R, Wada R, Moser B. Systems analysis for deployment of internet of things (IoT) in the maritime industry. J Mar Sci Technol 2021;26:459–69. https://doi.org/10.1007/s00773-020-00750-5.

4. Pham TY. A smart port development: Systematic literature and bibliometric analysis. Asian J Shipp Logist 2023;39:57–62. https://doi.org/10.1016/j.ajsl.2023.06.005.

5. Bechini A, Cimino MGCA, Marcelloni F, Tomasi A. Patterns and technologies for enabling supply chain traceability through collaborative e-business. Inf Softw Technol 2008;50:342–59. https://doi.org/10.1016/j.infsof.2007.02.017.

6. Kim HM, Fox MS, Gruninger M. An ontology of quality for enterprise modelling. Proc. 4th IEEE Workshop Enabling Technol. Infrastruct. Collab. Enterp. WET ICE 95, Berkeley Springs, WV, USA: IEEE Comput. Soc. Press; 1995, p. 105–16. https://doi.org/10.1109/ENABL.1995.484554.

7. Dobrovnik M, Herold DM, Fürst E, Kummer S. Blockchain for and in Logistics: What to Adopt and Where to Start. Logistics 2018;2:18. https://doi.org/10.3390/logistics2030018.

8. Kouhizadeh M, Sarkis J. Blockchain Practices, Potentials, and Perspectives in Greening Supply Chains. Sustainability 2018;10:3652. https://doi.org/10.3390/su10103652.

9. Kshetri N. 1 Blockchain’s roles in meeting key supply chain management objectives. Int J Inf Manag 2018;39:80–9. https://doi.org/10.1016/j.ijinfomgt.2017.12.005.

10. Chang SE, Chen Y-C, Lu M-F. Supply chain re-engineering using blockchain technology: A case of smart contract based tracking process. Technol Forecast Soc Change 2019;144:1–11. https://doi.org/10.1016/j.techfore.2019.03.015.

11. Marbouh D, Abbasi T, Maasmi F, Omar IA, Debe MS, Salah K, et al. Blockchain for COVID-19: Review, Opportunities, and a Trusted Tracking System. Arab J Sci Eng 2020;45:9895–911. https://doi.org/10.1007/s13369-020-04950-4.

12. Queiroz MM, Telles R, Bonilla SH. Blockchain and supply chain management integration: a systematic review of the literature. Supply Chain Manag Int J 2019;25:241–54. https://doi.org/10.1108/SCM-03-2018-0143.

13. Ngai EWT, Moon KKL, Riggins FJ, Yi CY. RFID research: An academic literature review (1995–2005) and future research directions. Int J Prod Econ 2008;112:510–20. https://doi.org/10.1016/j.ijpe.2007.05.004.

14. Wu NC, Nystrom MA, Lin TR, Yu HC. Challenges to global RFID adoption. Technovation 2006;26:1317–23. https://doi.org/10.1016/j.technovation.2005.08.012.

15. Castillo VS. Analysis of the scientific production on the implementation of artificial intelligence in precision agriculture. LatIA 2023;1:1-1. https://doi.org/10.62486/latia20231.

16. Zhong RY, Huang GQ, Lan S, Dai QY, Chen X, Zhang T. A big data approach for logistics trajectory discovery from RFID-enabled production data. Int J Prod Econ 2015;165:260–72. https://doi.org/10.1016/j.ijpe.2015.02.014.

17. Uniwersytet Jagielloński, Wyciślak S. Real-time visibility transportation platform deployment. Evidence from business practice and insights for theory. Gospod Mater Logistyka 2021;2021:2–18. https://doi.org/10.33226/1231-2037.2021.10.1.

18. Chopra S, Meindl P. Supply chain management: strategy, planning, and operation. Sixth edition, global edition. Boston Columbus Indianapolis New York San Francisco Amsterdam Cape Town Dubai London Madrid Milan Munich Paris Montréal Toronto Delhi Mexico City São Paulo Sydney Hong Kong Seoul Singapore Taipai Tokyo: Pearson; 2016.

19. Marwan, Yanis M, Muzakir, Nugraha GS. Application of QR codes as a new communication technology and interactive tourist guide in Jaboi, Sabang. IOP Conf Ser Mater Sci Eng 2020;796:012025. https://doi.org/10.1088/1757-899X/796/1/012025.

20. Suárez YS, Laguardia NS. Trends in research on the implementation of artificial intelligence in supply chain management. LatIA 2023;1:6-6. https://doi.org/10.62486/latia20236.

21. Lee I, Lee K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus Horiz 2015;58:431–40. https://doi.org/10.1016/j.bushor.2015.03.008.

22. Muñuzuri J, Onieva L, Escudero A, Cortés P. IMPACTS OF A TRACKING AND TRACING SYSTEM FOR CONTAINERS IN A PORT-BASED SUPPLY CHAIN. Braz J Oper Prod Manag 2016;13:352. https://doi.org/10.14488/BJOPM.2016.v13.n3.a12.

23. Liu Y, Takakuwa S. Modeling the materials handling in a container terminal using electronic real-time tracking data. Proc. 2011 Winter Simul. Conf. WSC, Phoenix, AZ, USA: IEEE; 2011, p. 1591–9. https://doi.org/10.1109/WSC.2011.6147876.

24. Madleňák R, Madleňáková L, Kolarovszká Z. System of Management and Traceability of Logistic Items through New Technologies. Procedia - Soc Behav Sci 2016;230:128–35. https://doi.org/10.1016/j.sbspro.2016.09.016.

25. Satoshi, Nakamoto. Bitcoin: A Peer-to-Peer Electronic Cash System n.d.

26. Nasih S, Arezki S, Gadi T. Blockchain technology impact on the maritime supply chain. Proc. 4th Int. Conf. Smart City Appl., Casablanca Morocco: ACM; 2019, p. 1–4. https://doi.org/10.1145/3368756.3369104.

27. Chang V, Baudier P, Zhang H, Xu Q, Zhang J, Arami M. How Blockchain can impact financial services – The overview, challenges and recommendations from expert interviewees. Technol Forecast Soc Change 2020;158:120166. https://doi.org/10.1016/j.techfore.2020.120166.

28. Guo Y, Liang C. Blockchain application and outlook in the banking industry. Financ Innov 2016;2:24. https://doi.org/10.1186/s40854-016-0034-9.

29. Araujo-Inastrilla CR, Vitón-Castillo AA. Blockchain in health sciences: Research trends in Scopus. Iberoam J Sci Meas Commun 2023;3. https://doi.org/10.47909/ijsmc.56.

30. Ettaloui N, Arezki S, Gadi T. An Overview of Blockchain-Based Electronic Health Records and Compliance with GDPR and HIPAA. Data Metadata 2023;2:166. https://doi.org/10.56294/dm2023166.

31. Suyambu GT, Anand M, Janakirani M. Blockchain – A Most Disruptive Technology On The Spotlight Of World Engineering Education Paradigm. Procedia Comput Sci 2020;172:152–8. https://doi.org/10.1016/j.procs.2020.05.023.

32. Mackey TK, Nayyar G. A review of existing and emerging digital technologies to combat the global trade in fake medicines. Expert Opin Drug Saf 2017;16:587–602. https://doi.org/10.1080/14740338.2017.1313227.

33. Chavez-Cano AM. Artificial Intelligence Applied to Telemedicine: opportunities for healthcare delivery in rural areas. LatIA 2023;1:3-3. https://doi.org/10.62486/latia20233.

34. Yli-Huumo J, Ko D, Choi S, Park S, Smolander K. Where Is Current Research on Blockchain Technology?—A Systematic Review. PLOS ONE 2016;11:e0163477. https://doi.org/10.1371/journal.pone.0163477.

35. Sunmola F, Burgess P. Transparency by Design for Blockchain-Based Supply Chains. Procedia Comput Sci 2023;217:1256–65. https://doi.org/10.1016/j.procs.2022.12.324.

36. Merkle RC. A Digital Signature Based on a Conventional Encryption Function. In: Pomerance C, editor. Adv. Cryptol. — CRYPTO ’87, vol. 293, Berlin, Heidelberg: Springer Berlin Heidelberg; 1988, p. 369–78. https://doi.org/10.1007/3-540-48184-2_32.

37. Cano CAG, Troya ALC. Artificial Intelligence applied to teaching and learning processes. LatIA 2023;1:2-2. https://doi.org/10.62486/latia20232.

38. Zheng Z, Xie S, Dai H, Chen X, Wang H. An Overview of Blockchain Technology: Architecture, Consensus, and Future Trends. 2017 IEEE Int. Congr. Big Data BigData Congr., Honolulu, HI, USA: IEEE; 2017, p. 557–64. https://doi.org/10.1109/BigDataCongress.2017.85.

39. Bonneau J, Miller A, Clark J, Narayanan A, Kroll JA, Felten EW. SoK: Research Perspectives and Challenges for Bitcoin and Cryptocurrencies. 2015 IEEE Symp. Secur. Priv., San Jose, CA: IEEE; 2015, p. 104–21. https://doi.org/10.1109/SP.2015.14.

40. Truong HTT, Almeida M, Karame G, Soriente C. Towards Secure and Decentralized Sharing of IoT Data. 2019 IEEE Int. Conf. Blockchain Blockchain, Atlanta, GA, USA: IEEE; 2019, p. 176–83. https://doi.org/10.1109/Blockchain.2019.00031.

41. Blossey G, Eisenhardt J, Hahn G. Blockchain Technology in Supply Chain Management: An Application Perspective, 2019. https://doi.org/10.24251/HICSS.2019.824.

FINANCING

Authors did not receive financing for the development of this research.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORSHIP CONTRIBUTION

Conceptualization: Safia Nasih; Sara Arezki; Taoufiq Gadi.

Research: Safia Nasih; Sara Arezki; Taoufiq Gadi.

Drafting - original draft: Safia Nasih; Sara Arezki; Taoufiq Gadi.

Writing - proofreading and editing: Safia Nasih; Sara Arezki; Taoufiq Gadi.