doi: 10.56294/dm2024360

Literature REVIEW

Literature review on artificial intelligence in dyeing and finishing processes

Revisión bibliográfica sobre la inteligencia artificial en los procesos de tintura y acabado

Mostafa El Khaoudi1

![]() *, Mhammed El Bakkali1

*, Mhammed El Bakkali1

![]() *, Redouane Messnaoui1

*, Redouane Messnaoui1

![]() *, Omar Cherkaoui1

*, Omar Cherkaoui1

![]() *, Aziz Soulhi2

*, Aziz Soulhi2

![]() *

*

1Higher School of Textile and Clothing Industries. Casablanca, Morocco.

2National Higher School of Mines of Rabat. Morocco.

Cite as: El Khaoudi M, El Bakkali M, Messnaoui R, Cherkaoui O, Soulhi A. Literature review on artificial intelligence in dyeing and finishing processes. Data and Metadata. 2024; 3:360. https://doi.org/10.56294/dm2024360

Submitted: 21-01-2024 Revised: 03-04-2024 Accepted: 21-06-2024 Published: 22-06-2024

Editor: Adrián Alejandro

Vitón Castillo ![]()

ABSTRACT

The finishing process in the textile sector is recognized as one of the most complex. This complexity arises from the diversity of structures, the multiple steps involved, the use of complex machinery, the variety of materials, chemicals and dyes, and the need to combine creativity and precision. Therefore, it is crucial to have tools that can improve efficiency, flexibility, and decision-making in this complex area. This literature review aims to provide relevant information on the use of digital engineering in the field of textile finishing. In this review, we used a systematic literature review methodology to examine how digital engineering is applied in the dyeing and finishing process. The data for this study was collected from reputed databases such as Science Direct, IEEE Xplore, Textile Research Journal and Google Scholar. We used the Prisma framework to select relevant articles, which led to the exclusive inclusion of journal articles in our literature review. A comprehensive framework has been developed to understand the impacts of using digital engineering. The approach presented in this framework provides a comprehensive and highly effective approach to addressing the complex challenges associated with ambiguity, modifications and subtleties frequently observed in the ennobling process. The results of various studies explored different aspects, such as properties of textile materials, chemicals and dyes, performance of finishing machines, organizational performance of finishing companies, as well as health concerns and safety at work. Although these studies have provided valuable solutions, they unfortunately remain insufficient to meet the requirements of the finishing process, which remains a complex area characterized by uncertainties, variations, and subtleties inherent to the practice. This particularity of each dyed and finished product promotes an environment conducive to experimentation and continued research.

Keywords: Fuzzy Logic; Artificial Neural Network; Genetic Algorithm; Expert System; Dyeing; Finishing.

RESUMEN

El proceso de acabado en el sector textil está reconocido como uno de los más complejos. Esta complejidad se debe a la diversidad de estructuras, los múltiples pasos implicados, el uso de maquinaria compleja, la variedad de materiales, productos químicos y tintes, y la necesidad de combinar creatividad y precisión. Por lo tanto, es crucial disponer de herramientas que puedan mejorar la eficacia, la flexibilidad y la toma de decisiones en este complejo ámbito. Esta revisión bibliográfica pretende aportar información relevante sobre el uso de la ingeniería digital en el campo del acabado textil. En este estudio, hemos utilizado una metodología sistemática de revisión bibliográfica para examinar cómo se aplica la ingeniería digital en el proceso de tintura y acabado. Los datos para este estudio se recogieron de bases de datos reputadas como Science Direct, IEEE Xplore, Textile Research Journal y Google Scholar. Se utilizó el marco Prisma para seleccionar los artículos pertinentes, lo que llevó a la inclusión exclusiva de artículos de revistas en nuestra revisión bibliográfica. Se ha desarrollado un marco exhaustivo para comprender las repercusiones del uso de la ingeniería digital. El planteamiento presentado en este marco ofrece un enfoque global y muy eficaz para abordar los complejos retos asociados a la ambigüedad, las modificaciones y las sutilezas que se observan con frecuencia en el proceso de ennoblecimiento.

Los resultados de diversos estudios exploraron diferentes aspectos, como las propiedades de los materiales textiles, los productos químicos y los tintes, el rendimiento de las máquinas de acabado, el rendimiento organizativo de las empresas de acabado, así como las preocupaciones en materia de salud y seguridad en el trabajo. Aunque estos estudios han aportado soluciones valiosas, lamentablemente siguen siendo insuficientes para satisfacer los requisitos del proceso de acabado, que sigue siendo un ámbito complejo caracterizado por incertidumbres, variaciones y sutilezas inherentes a la práctica. Esta particularidad de cada producto teñido y acabado promueve un entorno propicio para la experimentación y la investigación continua.

Palabras clave: Lógica Difusa; Red Neuronal Artificial; Algoritmo Genético; Sistema Experto; Tintura; Acabado.

INTRODUCTION

Artificial intelligence (AI) is a computer science field that explores intelligent tasks like human abilities, aiming to replicate human cognition and create comparable cognitive processes. It encompasses various methods like neural networks and fuzzy logic. Coined by McCarthy in 1956, AI’s significance was highlighted by Turing’s “Computing Machinery and Intelligence”(1) proposing the Turing test to evaluate machine intelligence.(2) AI is applied across multiple sectors, including robotics and natural language processing.

In the textile industry, colouring or dyeing has always been a precise process. Before the advent of computers and automation, people prepared dye mixtures, applied the dyes to fabrics, and controlled the dyeing. Initially, soft computing replaced human-driven procedures. AI, the next generation of soft computing, can now do anything humans can do. Thanks to AI, it is now possible to formulate reliable dyes, match colours and detect defects without human intervention. Besides colour recipe prediction, various researchers have focused on dyeing defects and dyeing difficulties. Huang et al.(3) classified seven categories of dyeing errors using image processing and fuzzy neural networks. Inconsistent colouring on the edge and fill band in the shade are among the defects. Construction of a fuzzy neural classification system by an expert system using a neural network as a fuzzy inference engine. The engine is trained on sample data.

Huang et al.(3) described the application of fuzzy logic to cotton colour grading to improve the acceptance of machine grading for cotton colours. Cotton colour grades are a few classes in colour space (Rd, b). Adjacent colour classes have fuzzy, overlapping boundaries, making sharp delineation methods ineffective for cotton colour grading. Fuzzy logic is specialised in dealing with uncertainty and imprecision in the decision-making process, and thus offers a new approach for cotton colour grading. In this paper, we present the procedures for building an inference system (FIS) using fuzzy logic to classify the main classes of cotton colours, and preliminary results to demonstrate the effectiveness of the FIS in reducing disagreements in colour grading. The FIS results show a high degree of consistency in cotton colour data over several years.(4) The performance of FIS e error and coefficient of determination (R 2) between the predicted and experimental values were found to be 0,536, 0,798 and 0,959, respectively. The results confirm that the model can be appropriately applied for the prediction of fabric whiteness index in textile. The performance of FIS mainly depends on the selections of input and output fuzzy sets, the design of membership functions and the establishment of fuzzy rules that guide the input-output relationships. These settings can be initially selected based on an analysis of a small data set, then refined through trial and error with more data. The workbooks’ knowledge of colour grading can be incorporated into the fuzzy rules for improve overall agreement with visual calibration. The Fis can perform consistent classifications for samples from different years. Preliminary results showed great potential as a more reliable way to classify cotton colours.

The Kubelka-Munk (K-M) model was used in recipe prediction systems of the early 1940s. In K-M theory, dyes are characterized by their absorption and diffusion coefficients, K and S. K-M theory is a two-stream version of a multiple-stream technique. Despite the existence of more accurate theories, the K-M theory is still widely used due to its simplicity and the ease with which it can determine the K and S coefficients. The K-M hypothesis is used to predict the colour of textiles, paints, and printing inks. The version of the theory used in this study concerns transparent printing inks, for which K and S must be fixed absolutely.(5) Westland showed in 2002 that K-M theory can map a colour vector c and a reflection vector r to represent the question of colour prediction. Multilayer perceptron’s (MLPs) can correctly reproduce any continuous feature to any degree. MLP stands for multi-layer processing unit. Units in the first layer (or input layer) are fed a real-world vector, while units in the final or output layer use the network output. Between the input and output layers there may be hidden levels of units. The results show that while ANNs can learn to map dye concentrations and spectral reflectance in theory, they struggle to beat the K-M model in practice. They showed the benefit of using separate training and testing sets to evaluate overall network performance. Computer programs based on artificial intelligence, called expert systems, have received a lot of attention and have been used to solve an impressive number of problems in various fields. Diagnosing dye problems was one of the first topics studied after the advent of digital computers, with the advent of artificial intelligence and expert systems. The performance of the system was tested and evaluated by human experts and was found to be very satisfactory. This provides a starting point for further improvements in the field of cotton dyeing. Knowledge can be taught to the expert system in several ways. In the article, they introduced knowledge in the form of rules. A rule has an antecedent and a result. The antecedent is the “if” component of a rule. The right side of the rule is called “then”.

Hussain et al.(6) evaluated their system: thus, although the Expert system is not flawless, it is better than individual experts. The main reason for the superiority of the expert system over human experts is that the expert system evaluates all probable causes, whether they are less prevalent or not. As a result, human experts are more likely to ignore probable reasons for an error than expert systems. The expert system beat human experts in identifying difficult dye defects.

SenthilKumar et al.(7) suggested using a neural network to create the desired colour depth. Expected colour depth is an important factor to achieve for batches. The batch must be returned for rework or rejected if the colour depth produced does not conform to the reference. The neural network, which was trained using input and output parameters related to the reactive HE dyes on the cotton fabric, has an error of 1 % in the dyeing time. The trained network provides the same percentage error when tested with a different colour and fabric. This was verified even as selected input and output parameters were beyond the range used to train the network. Therefore, the neural network can predict the main depletion and fixation times of high reactive dyes on cotton fabrics. SenthilKumar(8) found results from research on the use of neural networks to model CIELAB values. The L*a*b* values of the neural network constructed using the input and output parameters are less than 2,0 % for vinyl sulfone dyes. The trained network has the same percentage error when tested with dyes that were not used for training. The trained network provides the same percentage error even when the input and output parameters are beyond the range used for training. A value of DE* between 0-1,5, the difference between the calculated values and the predicted values, was obtained. Most samples have a brightness difference between 0,7 and 0,4, which is acceptable. The built-in neural network model can be used to optimize dyeing parameters for any vinyl sulfone dye. Golob et al.(9) demonstrated the possibility of using counter-propagation neural networks to identify dye combinations in textile printing paste formulations. An existing collection of 1430 printed samples produced with 10 dyes was used for training the neural networks. Reflectance values served as input data and known concentrations of one or two dyes. Dyes were used to print each sample. Some variations of the neural network parameters were tested to determine the best model, and a cross-validation method was used to estimate the generalization error. Additionally, some changes to input and output data have been made to improve learning capabilities.

In the present work, the effectiveness of artificial neural networks in assisting colorists in determining the appropriate colorants for obtaining the required color has been demonstrated. Although the initial effort of training a neural network and finding the optimal parameters are greater compared to other methods, the advantage of the neural network approach is that once the training phase is completed, Determination of new unknown samples is very simple and fast Further improvements could be made by transforming the reflectance values so that the concentration influence of different dyes is eliminated.

In a study by Khataee et al.(10), Chlamydomonas species demonstrated the ability to remove the triphenylmethane dye C.I. Basic Green 4 (BG4) through biosorption. The study examined various operational parameters such as initial dye concentration, temperature, pH, reaction time, and algae concentration and developed an artificial neural network (ANN) model to predict the bio-sorptive decolorization of BG4 solution. The ANN model showed a high predictive performance (R2 = 0,979) and identified initial dye concentration as the most significant factor, followed by temperature. An alkaline solution was found to be optimal for decolorization. The ANN model effectively captured the complex interaction process under different experimental conditions, enabling estimation of process behavior through simulation. The importance of input variables on color elimination efficiency was also assessed using the connection weights of the neural network.

Guruprasad et al.(11) conducted a review on the utilization of computational techniques in textile processes and products. They explored the concept of soft computing, which offers a flexible and simplified computing methodology. The review examines three primary branches of soft computing: fuzzy logic, neural networks, and genetic algorithms, focusing on their applications in solving diverse textile problems. These problems range from fibre classification and color grading to predicting yarn and fabric properties, optimizing products and processes, and even searching for aesthetically pleasing garment designs. The review highlights that these soft computing tools are not in competition but rather complementary to each other. The authors also discuss the development of hybrid prediction models that combine the strengths of these techniques. These hybrid models have the potential to establish smarter and more efficient prediction systems for problem-solving in the textile industry.

In a study conducted by Yadav et al.(12), the application of fuzzy logic in the textile industry was investigated. The study presented two examples that focused on utilizing fuzzy logic for process control in the sizing process and the condensation reaction of crosslinking agents. The primary aim was to achieve enhanced process control, leading to improved productivity and quality of the final textile product. Additionally, the study highlighted the potential indirect environmental benefits, including energy and chemical savings, that could be achieved through the implementation of improved process control methods.

In his thesis, Kalav(13) developed an expert system for troubleshooting inkjet printing on cotton substrates. The system addressed defects occurring before and after printing by examining the entire process from cotton production to fixing. Thirteen common symptoms and sixty-one potential causes were identified through literature review and expert input. Using a five-point scale, fifteen experts rated the likelihood of each cause matching each symptom. The system integrated this knowledge and employed a user-selected approach to problem-solving, effectively addressing multiple faults by starting with the common cause. The study aimed to create a cost-effective expert system for troubleshooting inkjet printing on cotton, serving as a training tool for new printers and reducing costs by detecting defects without additional fabric printing.

In their study, Nasiri et al.(14) proposed a novel approach called fuzzy pattern trees for modeling fuzzy systems. This approach was developed as an alternative to rule-based system architectures that are commonly used but have perceived limitations. Fuzzy pattern trees utilize a hierarchical and modular structure, employing various types of non-linear aggregation operators. This allows for a more flexible and concise representation of functional dependencies, striking a balance between model accuracy and transparency. The researchers evaluated this new model class in the context of a specific case study focused on modeling color yield in high-temperature polyester dyeing, considering factors such as disperse dye concentration, temperature, and time. They compared three different model building approaches: a purely knowledge-based approach, a purely data-driven approach, and a hybrid approach combining the two. The results demonstrated that fuzzy model trees outperformed conventional fuzzy modeling using Mamdani’s rules in terms of precision and interpretability, regardless of whether the models were built using knowledge-based or data-driven approaches. Furthermore, the study showed that the hybrid modeling approach, which combines expert knowledge and model calibration, outperformed both the purely data-driven and purely knowledge-driven approaches.

In his article, Banchero(15) aimed to offer readers an up-to-date overview of Supercritical Fluid Dyeing for both synthetic and natural textiles. The article covered a range of topics, including the solubility and equilibrium distribution of dyes, mass transfer phenomena, and interactions between solvents and polymers during the coloring process. Additionally, the article provided insights into the latest advancements in dyeing process technology. While the most promising results have been achieved in the dyeing of synthetic textiles, the author also emphasized the importance of dyeing natural textiles, which currently presents a limitation in this technology.

In a study conducted by Radhakrishnan(16), the aim was to investigate how varying experimental parameters such as pH, enzyme dosage, and temperature could impact the removal of natural and accidental impurities from knitted cotton and Lycra fabrics, with the goal of preparing them for dyeing and finishing processes. The researchers employed response surface methodology using the Box-Behnken model to determine the optimal experimental conditions and assess their effects. The optimal values were identified as a pH of 8,5, an enzyme dosage of 0,4 % (based on the fabric’s weight), and a temperature of 55°C. The obtained R2 values and F values demonstrated the significant combined effect of all parameters. The study’s findings indicated that the bio-scouring process executed under these optimized conditions was appropriate. The optimized conditions successfully fulfilled the pre-treatment requirements of achieving desirable absorbency and maintaining an acceptable weight loss range (between 3 % and 6 %). Since these conditions underwent statistical evaluation, they can be considered as the recommended treatment conditions for biological pretreatment. This research provides valuable insights for the textile industry by offering optimal parameters for effectively removing impurities prior to dyeing and finishing knitted cotton and Lycra fabrics.

Hossain et al.(17) employed a fuzzy logic expert system to model the color intensity of knitted cotton blend fabrics. The model considered dye concentration, dyeing time, and process temperature as factors influencing color intensity. The expert system was developed by translating the knowledge and experience of a dry cleaner into a set of expert system rules. The fuzzy logic toolbox in MATLAB was utilized to build the model, enabling the prediction of color intensity in textile dyeing operations based on specific requirements. The developed fuzzy expert system was flexible, allowing easy modifications in response to changes in dyeing process parameters.

Two years later, Hossain et al.(18) extended their research by developing color strength models for viscose/Lycra blended fabrics using a fuzzy logic approach combined with artificial neural networks. This approach required a large amount of experimental data, which can be time-consuming to acquire. To address this challenge, they proposed using a fuzzy logic expert system (FLES) that performs exceptionally well in nonlinear and complex systems, even with limited experimental data. To validate the developed fuzzy model, a laboratory-scale experiment was conducted, and various numerical error criteria were analysed. The results showed an average relative error of 3,80 %, a correlation coefficient of 0,992, and a goodness of fit of 0,986 between the actual and predicted color strengths of the fabrics. These findings demonstrated the effectiveness of the developed model in accurately predicting color strengths.

Hossain et al.(19) conducted a study focusing on the optimization of dyeing process parameters and the prediction of color strength for viscose/Lycra blended knitted fabrics using the Taguchi method. The primary objective was to determine the optimal dyeing conditions and forecast the color strength of these fabrics using the Taguchi method. The study considered controllable factors such as dye concentration, temperature, time, alkali concentration, salt concentration, and bath ratio as input variables, while fabric color strength served as the response variable for constructing the Taguchi model. An L25 orthogonal network model was selected, involving 25 experiments with three trials for each experiment. The mean absolute error and coefficient of determination (R2) between the actual and predicted color strength were found to be 3,48 % and 0,88, respectively. The results led to the conclusion that the Taguchi method is effective for optimizing and predicting fabric color strength in nonlinear and complex dyeing processes.

Hossain et al.(20) developed an intelligent model using a fuzzy knowledge-based expert system (FKBES) to predict color intensity in cotton knitwear. By considering dye concentration, dyeing time, and process temperature, the model addressed the nonlinearity and interdependencies of these factors, which posed challenges for traditional mathematical and statistical methods. Unlike approaches such as artificial neural networks and fuzzy neural models that require extensive experimental data, the FKBES performed exceptionally well with limited test data, similar to human experts. Laboratory-scale experiments on three types of cotton knitwear validated the model, demonstrating a high level of agreement between predicted and actual color intensity values, with an absolute error of less than 5 %.

Hossain et al.(21) aimed to predict the color intensity of viscose knitwear using a fuzzy logic (FL) model. The model incorporated the concentration of dye, salt concentration, and alkali concentration as input variables. The study also compared the performance of the FL model with an artificial neural network (ANN) model using the same parameters and data. The experimental results revealed that the dye concentration had the most significant impact on the color strength of viscose knitwear.

The FL model demonstrated a coefficient of determination (R2) of 0,977, a root mean square (RMS) error of 1,025, and a mean absolute error (MAE) of 4,61 % when comparing the predicted color intensity with experimental data. On the other hand, the ANN model showed an R2 of 0,992, an RMS error of 0,726, and an MAE of 3,28 %. Both models exhibited the ability to effectively predict fabric color intensity in a nonlinear domain, but the ANN model displayed higher prediction accuracy compared to the Fuzzy model.

In their study, Kabbari et al.(22) investigated the effects of an anti-stain treatment on the hydrophobic characteristics of knitted plush fabrics. They compared two modeling methods: a multi-criteria analysis using a response surface method, and a fuzzy logic modeling approach based on artificial intelligence. The study aimed to analyse the influence of operational parameters and intrinsic fabric characteristics on the outcomes, specifically the contact angle and air permeability.

To determine the most significant parameters, the researchers proposed an innovative approach employing fuzzy logic. The results indicated that air permeability is primarily influenced by parameters associated with the knitted structure, while variations in processing parameters have a substantial impact on the contact angle. As a result, the authors concluded that the implementation of artificial intelligence systems could effectively enhance the comprehension, evaluation, and prediction of hydrophobic properties in plush knitted fabrics within the knitting industry, surpassing the capabilities of multi-criteria analysis.

For dyeing planning whose optimization is very important for productivity, Huynh et al.(23), opted for a multi-subpopulation hybrid genetic algorithm for batch dyeing planning of textiles. Multifunctional textile is increasingly used for various purposes in sports, outdoor, urban, casual and industrial materials. Due to the shortening of product life cycles in the consumer era, the scheduling problem of textile batch dyeing which can be modeled as parallel batch processing machines with arbitrary working size, family incompatible jobs, different due date and sequence-dependent setup time has increasingly complicated product mixing, hence the need for intelligent production. To migrate to Industry 4.0, this study aims to develop a multi-subpopulation genetic algorithm with integrated heuristics (MSGA-H) to minimize the manufacturing time to improve the planning of batch dyeing of textiles which constitutes the bottleneck. Additionally, an approach combining state-of-the-art batch scheduling methods is developed for reference solutions. To estimate the validity of the proposed MSGA-H, an empirical study was conducted in a large vertically integrated textile manufacturer in Taiwan with different scenarios based on real-world settings. The results showed the practical viability of the proposed MSGA-H. This study concludes with a discussion of contributions and future research directions for smart production in emerging countries.

Tadesse et al.(24) conducted a study with the objective of predicting hand values (HV) and total hand values (THV) of functional tissues using a fuzzy logic model (FLM) and an artificial neural network (ANN) model. The evaluation of functional tissues was performed through subjective evaluation scenarios carried out by trained panels. Initially, the FLM was employed to predict HV based on finishing parameters. Subsequently, both FLM and ANN models were utilized to predict THV using the HV values.

The FLM demonstrated efficient estimation of HV, as evidenced by low root mean square error (RMSE) and mean relative percentage error (RMPE) values, except for bipolar descriptors which exhibited extremely low values within the fuzzy model. On the other hand, the prediction performance of both FLM and ANN models for THV was effective, with RMSE values of approximately 0,21 and 0,13, respectively. These values fell within the range of experimental variation. Additionally, the RMPE values for both models were below 10 %, indicating the robustness and efficiency of the models in accurately predicting THVs of functional tissues. Therefore, the FLM and ANN models hold promise as reliable tools for THV prediction in functional tissue analysis.

Haque et al.(25) conducted a study on the prediction of cotton whiteness index in cotton knitwear using a fuzzy inference system based on bleaching process variables. The researchers observed that the process parameters influencing the whiteness index of cotton knitwear exhibit highly nonlinear behavior. The fuzzy inference system was chosen as a promising modeling tool due to its ability to efficiently map nonlinear relationships with limited experimental data. Triangular-shaped membership functions were employed for the variables, and a total of 48 rules were generated for the system.

The study revealed that the impact of hydrogen peroxide concentration alone on whiteness was relatively small, but it was significantly influenced by temperature, even when the hydrogen peroxide concentration remained constant. To validate the proposed model, additional experimental data were used. The evaluation metrics, including root mean square error, mean absolute percentage error, and coefficient of determination (R2), between the predicted and experimental values were determined to be 0,536, 0,798, and 0,959, respectively. These results confirm the suitability of the model for predicting fabric whiteness index in the textile industry.

Haque et al.(26) investigated the prediction of burst strength in cotton knitted fabrics through the utilization of a fuzzy modeling approach based on bleaching process variables. The model incorporated hydrogen peroxide concentration, bleaching temperature, and bleaching time as input variables, while the variable of interest was the burst strength of the fabrics. By employing fuzzy expert systems, the study aimed to effectively capture the nonlinear relationships within the limited experimental data available. To validate the developed model, new sets of experimental data were used. The assessment metrics, including root mean square error, mean absolute percentage error, and coefficient of determination (R2), were calculated and yielded values of 4,89, 0,707, and 0,965, respectively. These findings demonstrate the successful application of the model in accurately predicting the bursting resistance of fabrics in textile dyeing workshops.

Yu et al.(27) developed three models combining least square support vector machine (LSSVM) and particle swarm optimization (PSO) to predict the K/S values of dyed cotton fabrics. The models utilized easily obtainable variables such as dye concentration and processing conditions as inputs. The predicted K/S values from the PSO-LSSVM model showed good agreement with the actual measurements. Comparisons with other models demonstrated the superior performance of the PSO-LSSVM approach. This study highlights the effectiveness of the PSO-LSSVM model as a powerful tool for predicting K/S values in reactive dye-dyed cotton fabrics, offering potential benefits in optimizing production processes and reducing costs in the textile industry.

Haji et al.(28) undertook a study to predict the color strength of plasma-treated wool yarns dyed with natural dye, aiming to overcome the challenge of low substantivity between Fibers and natural dyes. The study involved treating wool Fibers with oxygen plasma under different conditions and subsequently dyeing them with grape leaf extract. To evaluate the effects of plasma processing parameters on color intensity and their predictive capabilities, artificial neural network (ANN) and adaptive fuzzy neuro-inference system (ANFIS) models were employed. Variable factors such as oxygen flow, power, and duration were adjusted during the plasma treatment of wool yarns. The dyed samples underwent consistent conditions during the dyeing process using grape leaf extract. The ANN and ANFIS models were utilized to analyse and model the influence of plasma processing parameters on color intensity. The findings demonstrated that increasing the variables in the plasma treatment process, including oxygen flow, power, and duration, led to improved color strength in the dyed samples. The developed ANN and ANFIS models exhibited accurate predictions of the experimental data, with correlation coefficients of 0,986 and 0,997, respectively. ANFIS outperformed the ANN and a previous response surface methodology (RSM) model, achieving a higher correlation coefficient of 0,902.

Sarkar et al.(29) aimed to develop and validate a fuzzy logic-based model for predicting the GSM (grams per square meter) and crease recovery angle of laser-engraved denim. Laser engraving is a popular technique used to achieve a faded appearance on denim, offering advantages over conventional bleaching methods, such as improved productivity and reduced rejection rates. However, laser parameters like pixel time and dots per inch (DPI) have an impact on the GSM and wrinkle recovery angle of the treated denim. Despite the non-linear relationship between these parameters, a fuzzy logic-based model was created to demonstrate their effectiveness as input variables and predict GSM, warp ply recovery angle, and weft ply recovery angle as output variables. The model was validated through testing, with average relative errors of 1,68, 2,18, and 2,25 for GSM, warp ply recovery angle, and weft ply recovery angle, respectively. The determination coefficients (R2) were found to be 0,966, 0,952, and 0,958 for GSM, warp ply recovery angle, and weft ply recovery angle, respectively. The authors concluded that the developed model represents a novel approach for predicting GSM and crease recovery angle in laser-engraved denim, serving as a valuable decision support tool for garment design and clothing manufacturing, thereby saving process designers from extensive trial and error.

Kassim et al.(30) designed and implemented a straightforward water level indicator and controller based on fuzzy logic for industrial applications like nuclear power plant boilers and textile dyeing machines. The electronic level indicator used LEDs to define two levels, minimum and maximum. Their fuzzy logic controller (FLC), based on the Mamdani type fuzzy inference system, utilized level error and rate of change of error as inputs to determine the valve position. The FLC was implemented in MATLAB and simulated in Simulink to observe its behavior with changing inputs. Performance and reliability were verified by comparing the fuzzy controller’s response to that of a conventional PID controller. The results showed that the fuzzy logic controller achieved minimal overshoot and steady-state error, quickly stabilizing, and providing precise water level control. It proved suitable for rapid control with coarse adjustment. The designed controller is applicable for applications with periodically varying liquid levels. To further enhance accuracy, an optimized fuzzy logic controller with adjusted fuzzy parameters can be employed in future designs.

Ulucan-Altuntas et al.(31) conducted a study focused on the treatment of textile wastewater from industrial sources using an electrocoagulation process. The results were assessed using fuzzy logic, an artificial intelligence-based modeling technique widely employed in various environmental engineering applications, ranging from wastewater treatment to air pollution estimation. The study considered three variables: current density, initial pH, and electrolysis time, which were used to predict the efficiency of removing COD, total organic carbon (TOC), and color. Lower pH values were found to be more effective in COD and TOC removal, while higher pH values were effective in color removal. Among the variables, electrolysis time was identified as the most influential parameter for the electrocoagulation treatment, and the optimal reaction time was determined to be 15 minutes. The results were further evaluated using a multiple regression model, and the resulting equations were maximized to identify the optimal conditions. The optimal conditions determined were a current density of 60 mA/cm², pH 5, and a reaction time of 20 minutes. By implementing these parameters, the study achieved color, TOC, and COD removal efficiencies of 89 %, 86 %, and 61 %, respectively.

Farooq et al.(32) devised a shade prediction system utilizing artificial neural networks to quantify the change in shade resulting from the application of crease recovery finishing. Finishes are commonly applied to enhance the appearance, performance, and texture of fabrics. Anti-crease finishes create a three-dimensional cross-linking network on the surface of cotton knits to control their dimensions. However, the application of anti-crease finishes often leads to color changes in dyed fabrics. This article elucidates the phenomenon of tint change for various colors and tint percentages and proposes the use of an artificial intelligence-based prediction system to anticipate the tint behavior following the final finishing process. Individual neural networks were trained to predict the color of finite samples, represented by delta color coordinate values (ΔL, Δa, Δb, Δc, and Δh). The input variables for training the networks consisted of reflectance values (in the visible range of 400-700 nm) of the dyed samples, along with color, tint percentage, and finish concentration. The trained neural networks were validated using techniques such as “cross-validation” and “hold” methods. By combining the individually trained artificial neural networks, a hue prediction model was developed, which achieved a prediction accuracy of over 90 % for hue change. This system enables dyers to forecast shade alterations prior to dyeing and finishing, allowing them to adjust their recipes accordingly. Ultimately, this approach can reduce rework and reprocessing in the textile wet processing industry.

A study encountered challenges in developing predictive models due to the highly nonlinear mapping between observed dry and wet colors. To address this, they constructed a three-layer neural network model capable of predicting the color of dry cotton fabric based on its wet state. Multiple models were created based on the spin pressure, where the wet reflectance values in Lab* color space served as the input data for the models, and the neural network outputted the predicted Lab* values in the dry state. In the absence of the neural network, the color difference between the wet and dry fabric was found to range from 5 to 20 units of E2000 color difference. However, by incorporating the neural network, the model achieved accurate predictions of the dry fabric color from its wet state, with a color difference within one unit (as measured by the DE2000 equation) over 90 % of the time. The DE2000 color difference equation was utilized as a measure for training and testing the model, leading to faster convergence and improved accuracy. Importantly, this methodology is not limited to reactive dyes on woven cotton but can be generalized to different types of dyes and fabrics. It can be applied to generate prediction models and databases for various dye classes, including direct dyes, acid dyes, and other series of reactive dyes. Furthermore, with appropriate modifications, this approach holds potential for use in finishing processes such as coating and post-processing.(33)

De Sausa Causta et al.(34) conducted a systematic literature review in the field of production planning and control (PPC) tools/activities and their impact on eco-efficiency. The aim was to explore how integrating eco-efficient practices with conventional PPC tools/activities can lead to environmental and economic benefits. The study employed bibliometrics and a systematic review of literature to analyse the relationship between PPC and eco-efficient practices. Additionally, the authors utilized ucinet-Draw to examine the connection between conventional PPC tools/activities and eco-efficiency. The findings of the study revealed both theoretical and practical contributions. One notable contribution is the evolution of PPC utilization in conjunction with eco-efficiency in various industries. The study also identified potential areas for future research. Overall, the research indicated that PPC plays a crucial role in improving operational eco-efficiency. This is achieved through several mechanisms, including facilitating the remanufacturing, recycling, and reuse of materials, promoting the use of renewable resources, reducing waste generation, and minimizing energy and water consumption. The research serves as a valuable resource for further exploration and understanding of the relationship between PPC and eco-efficiency.

Luo et al.(35) undertook a comprehensive analysis titled “Evaluation Methods for Environmental Sustainability of Textiles and Apparel” in the Environmental Impact Assessment Review. The study emphasizes the significance of environmental sustainability in the decision-making process of textile and apparel companies, as it involves balancing economic productivity and environmental impact. However, assessing the environmental sustainability of textile products is challenging due to the intricate nature of their production and consumption processes. The article critically examines various evaluation methods that have the potential to measure environmental sustainability. These methods encompass life cycle analysis, environmental footprint, eco-efficiency, and the Higg index. The researchers thoroughly reviewed the methodologies employed by these approaches and discussed their limitations within the specific context of the textile and apparel industry.

In the Fibers and Polymers journal, Haji et al.(36) carried out a study titled “Modeling Environmentally Benign Dyeing of Polyester Fabric with Madder using Artificial Neural Network and Fuzzy Logic Optimized by Genetic Algorithm.” The research aimed to explore the dyeing process of polyester fabric with madder, a natural and eco-friendly dye. Using the Box-Behnken experimental design, the researchers dyed 46 samples of polyester fabric, varying five parameters: dye concentration, dye bath pH, temperature, duration, and liquor ratio. They measured the color strength (K/S) of the dyed samples and conducted multiple analyses of variance to assess the impact of each parameter on color intensity. To predict K/S values, they employed artificial neural network (ANN) and fuzzy logic models, each utilizing different parameters. The accuracy of the models was enhanced through the application of a genetic algorithm. The findings indicated that the best ANN model achieved an average absolute percentage error of 2,52, while the optimal fuzzy model achieved 3,01. Moreover, the researchers identified the most influential parameter on the ANN as dye concentration, whereas the liquor ratio had the least impact. Ultimately, the study examined the effects of each dyeing parameter on color intensity based on the established optimal ANN model.

Farooq et al.(37) present a paper that introduces an intelligent prediction method for estimating the shade change of dyed knitted fabrics after applying finishing. The method utilizes artificial neural networks (ANN) to predict the shade change of the dyed samples after the application of finish. Individual neural networks were trained to predict the delta values (∆L, ∆a, ∆b, ∆c, and ∆h) of the finished samples based on the reflection values of the knitted dyed samples, as well as the color, dye percentage, and finish concentrations of the knitted dyed samples, which were used as input parameters. The trained ANNs were validated using holdout and cross-validation techniques and then combined to develop the model. The developed system demonstrates a color change prediction accuracy of over 90 %, offering potential benefits in reducing rework and reprocessing in the wet processing industries.

Alam et al.(38) assert that artificial intelligence (AI) possesses the potential to bring about a revolutionary transformation in the wastewater treatment process. This review provides a comprehensive summary of the key AI tools utilized in water treatment, specifically focusing on the absorption of diverse pollutants. Various AI models, ranging from simple to hybrid, have effectively predicted the performance of different adsorbents in removing dyes, metals, organic compounds, pharmaceuticals, drugs, pesticides, and PCPs from water. Despite the numerous advantages offered by AI tools, certain limitations still persist.

Sarkar et al.(39) the primary aim of this study was to develop and assess a fuzzy expert model capable of predicting the tensile strength resistance of bleach-washed denim clothing. Based on the experimental results and a comparison with the model’s predicted values, the following conclusions can be drawn: the average relative error of tensile strength between the predicted and experimental values was found to be 2,82 % for the warp direction and 3,92 % for the weft direction, both within the acceptable range of 5 % confidence interval. Analysis and calculations revealed a high correlation coefficient (R) of 0,99 between the predicted and experimental values of tensile strength. The coefficient of determination (R2) for the tensile strength in both the warp and weft directions was 0,99, indicating a strong alignment between the model data and experimental data, demonstrating the model’s compatibility. The developed model offers the advantages of being time-efficient, highly customizable, and efficient in terms of materials and processes, thereby reducing the environmental footprint. Additionally, the model can be extended to model parameters other than bleach washing.

For future research, the effectiveness of fuzzy logic modeling can be explored for fabric types other than denim, considering other physical, mechanical, and color properties, and incorporating a wider range of processing values.

Sarkar et al.(40) conducted a study aiming to develop a fuzzy logic-based model for predicting the tear strength of laser-etched denim garments. The tear resistance of the warp and weft directions of laser-engraved denim clothing was predicted using two crucial laser parameters: dots per inch (DPI) and pixel time (PT). Laser engraving is a commonly employed method in clothing washing factories due to its lower health risks, speed, and precision compared to other processes. However, precise control of laser parameters is crucial because insufficient tear strength in treated garments may lead to rejection. In this research, a fuzzy logic-based approach was utilized to develop a prediction model for determining the tear resistance of laser-engraved denim. The model exhibited a consistent trend with the experimental results, indicating that tear strength decreases as DPI, PT, or both decreases. The average relative errors for warp and weft tear strength were found to be 3,34 % and 3,53 %, respectively, which fall within acceptable limits. The coefficient of determination (R2) for both warp and weft tear strength was 0,98 (R=0,99), suggesting that approximately 98 % of the total changes in tear strength for both directions can be attributed to the model.

Based on the results, it is evident that the proposed model can satisfactorily predict the tear strength of laser-etched denim garments. This has significant implications for the laser engraving denim industry and can aid in optimizing laser parameters to ensure adequate tear resistance.

Vadood et al.(41) studied the dyeing process of cotton fabrics using alum as a mordant and natural dyes, solder and madder. They examined the impact of different combinations of mordant, solder, and madder on color coordinates. The goal was to develop an accurate model for predicting cotton fabric color coordinates. They compared regression methods with weighted artificial neural network (ANN) models using optimization algorithms such as PSO-FMIN, BP, genetic algorithm, particle swarm optimization, gray wolf optimization, and FMINCON. The mean square error (MSE) was used for comparison.

The results showed that using the PSO-FMIN algorithm improved the accuracy of the ANN model in predicting color coordinates. The MSE values obtained for the l*, a*, and b* coordinates were 2,02, 1,68, and 1,39, respectively. These values were 44 %, 23 %, and 26 % better than using BP alone. Statistical analysis confirmed a significant relationship between the independent parameters (mordant, solder, and madder) and all color coordinates. Initially, linear regression was attempted but did not provide satisfactory accuracy. Therefore, an ANN model was employed, combining BP and optimization algorithms to determine the weights and biases. Using only optimization algorithms did not yield high accuracy, indicating a limitation of the method. However, when the weights and biases obtained from BP were used as the starting point for the optimization algorithms, the accuracy of color coordinate prediction significantly improved compared to using BP or the optimization algorithms alone.

Ghanmi et al.(42) conducted a study comparing fuzzy logic and response surface methodologies for predicting the dyeing behavior of wool and polyamide Fibers using Juglans R. extract. The study focused on examining the effects of extract concentration (0,05 % to 0,5 %), dyeing time (5 to 45 minutes), and temperature (50°C to 95°C) as input variables, with color intensity (K/S) measured as the output variable. The performance of the models was evaluated using root mean square error (RMSE), relative mean absolute error (RMAE), and mean relative percentage error (MRPE) as criteria.

The results showed that the MRPE values ranged from 0,25 % to 0,6 %, which is considered low and significant based on existing literature. The RMSE values were lower than the standard deviation of K/S, indicating a good fit of the models. Both methodologies demonstrated their ability to predict color intensity measurement. However, when comparing their performance criteria, the fuzzy logic methodology outperformed the response surface methodology, yielding lower error values. This suggests that the fuzzy logic approach was more effective in predicting the dyeing behavior of wool and polyamide Fibers with Juglans R. extract.

Cournoyer et al.(43) authored a review article titled “Electrodialysis Processes an Answer to Industrial Sustainability: toward the Concept of Eco-Circular Economy?” which was published in the journal Membranes. The review article examines a range of electrodialysis (ED) processes, including conventional ED, selective ED, ED with bipolar membranes, and ED with filtration membranes. These processes have consistently demonstrated their potential and eco-efficiency over the past few decades. The article specifically highlights the recent opportunities for resource valorisation in diverse industrial sectors such as water, food, mining, and chemistry. By implementing electrodialysis processes, these sectors can effectively manage waste or by-product resources, thus contributing to enhanced global industrial sustainability. The adoption of electrodialysis processes facilitates the transition from linear production systems to circular processes, aligning with the principles of an eco-circular economy.

Pervez et al.(44) conducted a study titled “Optimization and prediction of cotton fabric dyeing process using machine learning approach integrated with Taguchi design” published in Scientific Reports. The research aimed to propose a sustainable and beneficial cotton fabric reactive dyeing process by combining design of experiments and machine learning prediction models.

The study utilized a least squares support vector regression (LSSVR) model based on the Taguchi orthogonal statistical design (L27) to predict various dyeing performance parameters, including exhaustion percentage (E%), fixation rate (F%), total fixing efficiency (T%), and color strength (K/S). The results indicated the potential of the LSSVR model as a prediction tool in the textile industry during the dyeing process stage. The study introduced the LSSVR model specifically for cotton fabric dyeing process optimization, highlighting its suitability for such applications, and recommending its use in similar cases. Further research is needed to explore the incorporation of other algorithms to enhance the prediction ability of the LSSVR model. Additionally, attention should be given to new features and expenses associated with improving the dyeing process of cotton textiles within the context of the Sustainable Textile Industry 4.0 framework.

Vadood et al.(45) studied the prediction of color coordinates for cotton fabric dyed with natural madder and solder dyes using artificial intelligence. They explored various models, including regression, artificial neural networks (ANN), fuzzy logic, and support vector machines (SVM), to establish the relationship between material concentration and color coordinates. Optimization techniques like genetic algorithm, particle swarm optimization (PSO), and Gray wolf optimization (GWO) were employed to enhance model accuracy. The results showed high accuracy for all color coordinates, with the ANN optimized by GWO performing best for L* and b*, and the ANN optimized by PSO achieving the lowest mean absolute percentage error (MAPE) for a*. This study demonstrates the potential of AI models in predicting color coordinates for dyed cotton fabric, offering practical applications.

Irshad et al.(46) conducted research on textile finishing, which is the final step in enhancing fabric aesthetics and functionality. However, it can lead to undesirable effects like color change and variations in mechanical properties, causing significant losses for the textile industry. To address this problem, the researchers developed an artificial intelligence-based system to predict color behavior before finishing. The system utilized artificial neural networks trained with input data including color, tint percentage, finish type, finish concentration, and reflectance values in the visible range. Five networks were trained individually for color coordinates Δ (△L, △a, △b, △C, and △h). The networks were tested and cross-validated with 85 % accuracy. The developed models successfully predicted color variations (△L, △a, △b, △C, and △h) with mean absolute errors indicating a close correlation between actual and predicted values. The research highlights the potential of artificial intelligence in predicting color behavior during textile finishing, providing valuable insights to reduce losses and improve decision-making processes in the industry.

El Bakkali et al.(47) in his paper he investigates about the prediction of the weavability of a new fabric at the time of its creation. Using artificial intelligence (fuzzy logic), he shows the feasibility of a decision support model for designers and production experts.

Messnaoui et al.(48) investigated the exploration and employment of fuzzy logic in such applications have continued to evolve over time. It also uses fuzzy rules to express and justify inaccurate or heuristic knowledge. The realm of artificial intelligence, with its vast breadth and scope, permeates a diverse array of disciplines and sectors, traversing numerous spheres such as automation, decision-making, process control, planning, resource management, and healthcare, among a multitude of others.

METHOD

This study uses the Prisma framework and systematic literature review method to conduct an in-depth literature review. Mateo(49) proposed a series of specific steps for conducting a literature review systematically in 2020; these steps were rigorously followed in our research project. These procedures mainly include the development of a search strategy, the specification of selection criteria and the implementation of a comprehensive quality assessment and data extraction process. Then, in the following sections, we provide an in-depth explanation of each of these steps. Understanding the structure of the Prisma framework is essential to carrying out this research. Therefore, we developed a research paradigm:

· Section 2 – Research Technique: this section details the research method used in the study. It may include information on the data sources used, article selection, inclusion and exclusion criteria, and search strategies used to identify relevant studies. It provides a solid basis for understanding how the study was conducted.

· Section 3 – Literature Review: in this section, a literature review is presented. It highlights the articles that were retrieved for the study, and which deal with the use of artificial intelligence in finishing processes. The literature review may include a synthesis of key findings, trends, and gaps identified in the articles reviewed. It allows readers to familiarize themselves with the current state of knowledge on the subject.

· Section 4 – Discussion: the discussion section is where the results of the study are interpreted and discussed in depth. Researchers can analyse the implications of the results, compare them with other similar studies, discuss the limitations of the study and possible future research directions. This section allows the authors to present their thoughts and critical analyses on the results obtained.

· Section 5 – Future Research Perspectives: in this section, the authors explore future research perspectives in the studied area. They may identify unresolved questions or problems that merit additional attention, suggest promising avenues of research, or propose methodological improvements for future studies. This section draws attention to upcoming research opportunities and encourages readers to continue investigation.

· Section 6 - Conclusions: the conclusions section summarizes the main points covered in the study. It may include a summary of key results, an assessment of whether the objectives set at the outset have been achieved, as well as recommendations or practical implications arising from the study. The conclusions provide closure to the article and allow readers to grasp the main conclusions of the study.

To obtain the first results, exhaustive research was carried out by consulting different academic and scientific resources. Platforms such as ScienceDirect, IEEE Xplore, Journal of Textile Research, and Google Scholar were used to identify relevant articles around study. Once the preliminary data was collected, it was subjected to various circumstances and selection criteria. Researchers had to consider specific restrictions related to the research area, such as the geographic or thematic scope of the study. Additionally, the language of the articles was taken into consideration, generally choosing articles available in English for ease of understanding and accessibility. Also among the selection criteria was the nature of the articles, which included both original research articles and review articles. This made it possible to obtain a global and in-depth vision of the subject. In addition, time constraints were considered, focusing on articles published in a specific period, depending on the relevance and timeliness of the information sought. The researchers carefully analysed and evaluated each article to determine whether it met the study objectives and criteria. Only the most relevant, applicable, and high-quality studies were selected for inclusion in the comprehensive review of existing literature. However, any research article that did not meet the criteria of the established selection process was not included in this investigation. This ensures that only the most reliable and relevant sources are considered in the study, enhancing its credibility and quality.

Figure 1. Structure of the Scientific Review Process Used

Prisma Framework

Step 1. Identification

First, we need to develop a research strategy suitable for this study. For this, we used four databases: ScienceDirect, IEEE Xplore, Textile Research Journal and Google Scholar. The search keywords used are as follows: digital engineering, fuzzy logic, artificial neural network, genetic algorithm, machine learning, expert system, dyeing, finishing, textile, dye. Initially, 2087 documents were identified using this search strategy. Figure 2 illustrates the process of identifying the Prisma command, which was used to develop the search strategy.

Figure 2. Identification phase of Prisma framework

Step 2. Evaluation

In the second stage of the Prisma model, we assess and filter out pertinent information. This critical step involves establishing search criteria and effectively implementing them. Our primary objective is to compile a comprehensive collection of literature that explores artificial intelligence and its application in dyeing and finishing processes. To ensure accuracy, we have limited our investigation period from 2000 to 2024. Furthermore, this study exclusively focuses on exploring how artificial intelligence can be applied in different dyeing and finishing processes, narrowing down our research scope accordingly. Only complete articles and review articles were chosen, and the research papers were restricted to the English language. Notably, a total of 1810 documents were excluded during the selection phase, while 267 research documents were extracted and proceeded to the next stage. The selection process, following the Prisma framework, is elucidated in figure 3.

Figure 3. Screening phase of the Prisma Framework

Step 3. Meeting the requirement

This research primarily focuses on full-length research articles and review articles. To maintain accuracy, we conducted a meticulous screening process to eliminate any duplicate material. The abstract of each article was carefully evaluated to ensure its alignment with our objectives, and all the selected articles underwent a thorough review. Furthermore, we identified that 124 articles did not meet our specific requirements. After the screening process, 143 articles successfully passed this milestone and were deemed eligible for further analysis regarding their inclusion or exclusion. A visual depiction of the quality assessment process can be found in figure 4.

Figure 4. Eligibility phase of Prisma Framework

Step 4. Inclusion et exclusion

The inclusion and exclusion criteria were explicitly defined, and after a comprehensive examination and evaluation of all the extracted documents, 95 documents were excluded from the study. In the end, a total of 47 articles were chosen for the literature review. The incorporation phase of the Prisma guidelines is depicted in figure 5.

Figure 5. Inclusion stage of Prima Framework

RESULTS

Demographics

Contribution by Publishers

At this stage, the contributions of different publishers have been identified, as depicted in figure 6. Elsevier is at the top, with a maximum number of publications of 8 articles. Taylor and Francis ranked second with 7 articles then we have NISCAIR in a third place with 5 articles, and other articles published by different publishers like Emerald gp, Coreen company of Fibers and Wiley-Blackwell.

Figure 6. Publishers Contributions

Contribution by Journal

The data is collected from various sources. The sources used to search and select articles on dyeing and finishing technology and the use of artificial intelligence are listed in table 1.

|

Table 1. Contribution by journals |

|||

|

Year |

Journal |

Abbreviation |

Impact Fact |

|

2001 |

Textile Research Journal |

Text. Res. J |

2,3 |

|

2002 |

Textile Research Journal |

Text. Res. J |

2,3 |

|

2022 |

Research Journal of Textile and Apparel |

RJTA |

1,5 |

|

20O2 |

spiedigitallibrary |

spie |

0,37 |

|

2005 |

Design and development Coloration Technology |

S.D.C |

0,342 |

|

2004 |

Elsevier Dye. Pigment |

Elsevier Dye. Pigment |

4,71 |

|

2007 |

ElsevierDye.pigment |

ElsevierDye.pigment |

4,71 |

|

2008 |

Fibres Text. East. Eur. |

Fibres Text. East. Eur. |

0,9 |

|

2009 |

Environ. Technol |

Environ. Technol |

2,8 |

|

Year |

Journal |

Abbreviation |

Impact Fact |

|

2010 |

Indian J. Fibre Text. Res |

Indian J. Fibre Text. Res |

0,82 |

|

2010 |

Oriental Journal of Chemistry |

O J C |

0,5 |

|

2013 |

Proc. 2013 Jt. IFSA World Congr. NAFIPS Annu. Meet. IFSA/NAFIPS 2013 |

NAFIPS 2013 |

0 |

|

2013 |

Color. Technol |

Color. Technol |

1,8 |

|

2013 |

researchgate |

researchgate |

4,3 |

|

2013 |

ICMIME2013 |

ICMIME2013 |

2,9 |

|

2015 |

Journal of Engineered Fibers and Fabrics |

J. Eng. Fiber. Fabr |

2,347 |

|

2015 |

The Journal of The Textile Institute |

J. Text. Inst |

1,77 |

|

2016 |

The Journal of The Textile Institute |

J. Text. Inst |

1,77 |

|

2017 |

The Journal of The Textile Institute |

J. Text. Inst |

1,77 |

|

2018 |

Computers & Industrial Engineering |

Comput. Ind. Eng |

7,9 |

|

2018 |

Fashion and Textiles |

Fash. Text |

2,79 |

|

2019 |

Textile Research Journal |

Text.Res.J. |

2,3 |

|

2018 |

AATCC Journal of Research |

AATCC J. Res |

0,778 |

|

2020 |

Textile Research Journal |

Text. Res. J |

2,3 |

|

2019 |

Pigment Resin Technology. |

Pigment Resin Technol. |

1,66 |

|

2021 |

IOSR Journal of Electronics and communication |

IOSR J. Electron |

3,26 |

|

2020 |

Journal of Engineering and Applied Science |

JEAS |

1,3 |

|

2021 |

Journal of Water Chemistry and Technology |

J. Water Chem. Technol |

0,484 |

|

2021 |

The Journal of The Textile Institute |

J. Text. Inst |

1,77 |

|

2021 |

Production Planning & Control |

PPC |

7,9 |

|

2021 |

Elsevier Science direct |

Elsevier Science direct |

4,5 |

|

2021 |

Fibers and Polymers |

Fibers Polym |

2,5 |

|

2021 |

AUTEX Research Journal |

AUTEX Res J |

1,4 |

|

2022 |

Chemical Engineering Journal |

Chem. Eng. J. |

15,1 |

|

2022 |

Research Journal of Textile and Apparel |

Res.J. Text. Appar |

2,08 |

|

2022 |

Heliyon |

Heliyon |

4 |

|

2022 |

Coatings |

Coatings |

3,4 |

|

2022 |

Fibers and Polymers |

Fibers Polym |

2,5 |

|

2023 |

Membranes (Basel) |

Membranes (Basel) |

4,3 |

|

2023 |

Scientific Reports |

Sci. Rep. |

4,6 |

|

2023 |

SpringerLink |

SpringerLink |

7,4 |

|

2023 |

Journal Of Natural Fibers |

J. Nat. Fibers |

3,5 |

Contribution by Authors

The table below lists the top writers who made the most contributions to the fields of Artificial intelligence and dyeing process (Table 2).

|

Table 2. Author’s contributions |

||

|

Author’s Affiliation |

Number of Citation (2024) |

|

|

B. L. Iverson |

Department of Chemical Engineering, University of Texas, Austin, TX 78712 |

21306 |

|

A. R. Khataee |

Faculté de chimie, Département de chimie appliquée, Université de Tabriz, Tabriz, Iran |

35170

|

|

S. Westland |

Université de Leeds |

5408 |

|

T. Hussain |

National Textile University, Faisalabad |

4618 |

|

Chung FengJeffrey Kuo |

Université nationale des sciences et technologies de Taiwan |

4110 |

|

Aminoddin Haji |

Département d'ingénierie textile, Université de Yazd |

3036 |

|

M. Banchero |

Professeur associé, Politecnico di Torino |

1978 |

|

M. Sentilkumar |

University, Chennai, Inde |

1816 |

|

|

|

|

|

Pervez, Md Nahid |

Université d'État de New York AlbanyCe lien est désactivé., Albany, États-Unis |

1679 |

|

A. N. M. A. Haque |

Chercheur associé |

848 |

|

Authors |

Author’s Affiliation |

Number of Citation (2024) |

|

J. Lassègue |

CNRS, Paris |

841 |

|

M. G. Tadesse |

Université de Boras (Suède), Université technique Gheorghe Asachi (Roumanie) |

623 |

|

B. xu |

The University of Texas at Austin |

607 |

|

Kubra ULUCAN-ALTUNTAS |

Université des études de Padoue |

563 |

|

Morteza Vadood |

Département d'ingénierie textile, Université de Yazd |

477 |

|

C. C. Huang |

Département de science et d'ingénierie des matériaux, Université nationale des sciences et technologies de Taiwan, Taipei |

484 |

|

Gulzar Alam

|

Chercheur doctorant, Université d'Ulster |

378 |

|

Nhat-To Huynh |

Université de Danang - Université des Sciences et Technologies |

315 |

|

Joy Sarkar |

Université d'ingénierie et de technologie de Khulna | KUET · Département d'ingénierie textile |

274 |

|

I. Hossain |

Université d'ingénierie et de technologie de Khulna |

268 |

|

Hanen Ghanmi |

Ecole Nationale d'Ingénieurs de Monastir, Université de Monastir |

154 |

|

R. Guruprasad |

Laboratoires de recherche IBM Inde |

153 |

|

S. Radhakrishnan |

Textiles and clothing sustainability |

143 |

|

Luo, Yan |

Institut de la mode, Université Donghua, Shanghai 200051, Chine |

140 |

|

M. Nasiri |

Université iranienne des sciences médicales |

78 |

|

Chengbing Yu |

School of Materials Science and Engineering, Shanghai University, Shanghai, China |

72 |

|

Farida Irshad |

Département de technologie des fibres et des textiles, Université d'agriculture, Faisalabad, Pakistan |

28 |

|

Shakiru Olajide Kassim |

Université d'Aberdeen |

11 |

|

M. Kabbari |

Fibres et polymers |

6 |

Contribution by countrys

According to the figure 7 the United state, Iran, UK, and Pakistan are the countries that provide the most citations to this field.

Figure 7. Details of a country-specific citation

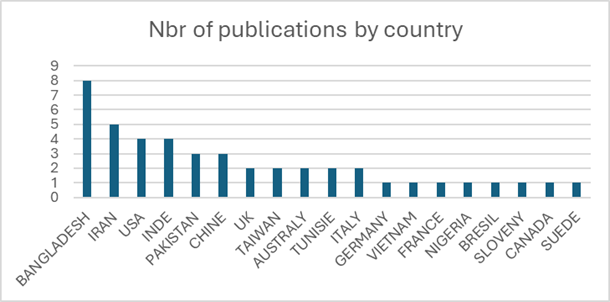

According to the figure 8, Bangladesh, Iran, USA, and India are the countries that provide the most publications to this field.

Figure 8. Details of a country- specific publication

Year-Wise Publications

In this segment, we will provide an overview of various articles categorized by their publication years. Figure 8 illustrates a significant increase in the number of articles published recently, which can be attributed to the growing recognition of Artificial Intelligence as an incredibly powerful tool for streamlining the dyeing process and aiding decision-making.

Figure 9. Data on publications by year

Classify

This study examines two terms: artificial intelligence and the enhancement process. Regarding the enhancement process, we have divided artificial intelligence into several main axes:

1. Artificial intelligence and dyeing defects (DD).

2. Artificial intelligence and cotton color grading (CG).

3. Artificial intelligence and spectral reflectance (SR).

4. Artificial intelligence and deep shade of coloration (PSC).

5. Artificial intelligence and water treatment (WT).

6. Artificial intelligence and troubleshooting ink jet printing (PR).

7. Artificial intelligence and color strength of fabric (PCS).

8. Artificial intelligence and mechanical properties of fabric (PM).

9. Artificial intelligence and shade change in finishing process (PSC)

In table 3, a detailed explanation of each study is provided following the structure of the article, according to the research objectives, the methodology used, and the results obtained.

|

Table 3. Detailed comparison of research article |

||||||||||||

|

Reference 3

|

Hybrid Fuzzy, NN |

X |

Objective |

The present study focuses on investigate recognition of seven kinds of dyeing defects: filling band in shade, dye and carrier spots, mist, oil stain, tailing, listing, and uneven dyeing on selvage. |

||||||||

|

Dyeing process |

DD |

X |

Method |

The fuzzy neural classification system is constructed by a fuzzy expert system with the neural network as a fuzzy inference engine. The neural network is trained to become the inference engine using sample data. |

||||||||

|

DM

|

|

|||||||||||

|

PS |

|

Results |

The results demonstrate that the fuzzy neural network approach can precisely classify these samples by the features selected. results demonstrate that the fuzzy neural net- work can precisely classify the testing samples with an RMS error of 0,001103 |

|||||||||

|

WT

|

|

|||||||||||

|

Reference 4

|

Fuzzy Infere system

|

X |

Objective |

This paper describes the application of fuzzy logic to cotton color grading to improve the acceptance of machine grading for cotton colors. |

||||||||

|

Dyeing process |

DD |

|

Methode |

In this paper, we present the procedures for constructing a Fuzzy inference system (FIS) using fuzzy logic to classify major classes of cotton colors, and the preliminary results to demonstrate FIS effectiveness in reducing machine-classer disagreements in color grading. |

||||||||

|

CG |

X |

|||||||||||

|

PS |

|

Results |

The results from the Fis show great consistency for multiple year of cotton color data. the preliminary results have shown great potential as a more reliable way of grading cotton colors. |

|||||||||

|

WT

|

|

|||||||||||

|

Reference 5

|

Artificial Neural Network |

X |

Objective |

This study investigates the ability of ANNs to predict spectral reflectance from colorant concentrations using a set of data measured from known mixtures of lithographic printing inks. |

||||||||

|

Dyeing process |

DD |

|

Method |

The network reached the best performance with 10 units in the hidden layer. A modified version of the algorithm was then used whereby the learning rate linearly reduced during training from 0,2 to 0,05 (algorithm implemented by the training function trained). |

||||||||

|

CG |

|

|||||||||||

|

SR

|

X |

|||||||||||

|

WT |

|

Results |

RMS error of 0,05. DE between actual and predicted reflectance for the test set is 8,23 units which is much greater than the value of 2,9 that can be obtained using the K-M model |

|||||||||

|

Reference 6

|

Expert system D’expert |

X |

Objective |

The aim of this research was to develop a knowledge-based expert system in the knowledge domain of troubleshooting problems in the dyeing of cotton |

||||||||

|

Dyeing process |

DD |

X |

Method |

Sources of knowledge included books, journals, manuals, case studies, the internet, dye manufacturers, machinery manufacturers and expert dyers |

||||||||

|

CG

|

|

|||||||||||

|

PS |

|

Results

|

Was demonstrated the design and explained the methodology employed for the development of ‘Dexpert’ |

|||||||||

|

WT |

|

|||||||||||

|

|

Artificial Neural Network |

X |

Objective |

An attempt made on the prediction of dyeing time. required to achieve expected depth of shade in the application of reactive HE dyes on cotton fabric using ANN is reported in this paper |

||||||||

|

Dyeing process |

DD |

|

Method |

The software used in this study was a feed forward. back propagation network. To carry out prediction, the network was trained with training patterns namely input and output parameters |

||||||||

|

CG

|

|

|||||||||||

|

PS |

X |

Results |

The results obtained from the network gives an average training error of around 1 % in the prediction of the time duration for achieving the correct depth of shade. |

|||||||||

|

TW |

|

|||||||||||

|

Reference 8

|

Artificial Neural Network |

X |

Objective |

the use of neural networks to model CIELAB values for predicting |

||||||||

|

Dyeing process |

DD |

|

Method |

the neural network constructed using the input and output parameters are less than 2,0 % for vinyl sulfone dyes |

||||||||

|

CG |

|

|||||||||||

|

PS |

X |

Results |

the difference between the calculated values and the predicted values, was obtained. Most samples have a brightness difference between 0,7 and 0,4, which is acceptable |

|||||||||

|

Reference 9

|

Artificial Neural Network |

X |

Objective |